a.前后视检查是检查跟踪仪的双轴转台系统旋转180度后的封闭性的操作,QVC补偿(1点QVC或者Full QVC)则利用该封闭性对转台系统进行精度补偿;

b.跟踪仪来到后视状态下,无法完成锁定的原因较多,首先需要检查在该点处测距系统是否能够正常工作,即Laser Intensity和ADM Intensity是否大于0.25,参见问题6的步骤e;

c.然后需要检查跟踪仪以及用于校准补偿的靶球架设是否稳固,跟踪仪必须使用专用三脚架,磁力吸盘或其它API认可的安装固定方式架设,严禁将跟踪头直接放置在支撑面上,这是因为跟踪头旋转时有较大的扭矩作用在底座上,将无法保证底座的稳定性和测量的重复性,并将对补偿结果产生不可预期的影响,检查和补偿用的靶球必须放置在靶座或者校准三脚架上,且放置于稳定的平面上并在整个测量过程中不得移动;

d.如果跟踪仪由于以前错误的QVC补偿而导致不能够在后视状态下锁定靶球,则需要恢复整个prm文件或者部分参数并重新进行QVC补偿,请参考问题8步骤g;

e.在确保跟踪仪和靶球都架设稳定的前提下,在后视状态如果激光指向偏离靶球少许,允许用手推动跟踪头帮助锁定靶球,这在一些比较老旧的跟踪仪上比较常见;

f.另一种办法是用热熔胶固定靶球座,以确保靶座具有重复定位靶球的功能(不得在校准三脚架上进行这个操作),然后在出现后视状态无法锁定时拿起靶球对准激光,锁定以后立刻将靶球放回靶座继续校准补偿操作;

g.无论采用上述何种方式完成的QVC补偿,在更新prm文件以后都需要再次重复检查同一位置,确保补偿结果应用正确;

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

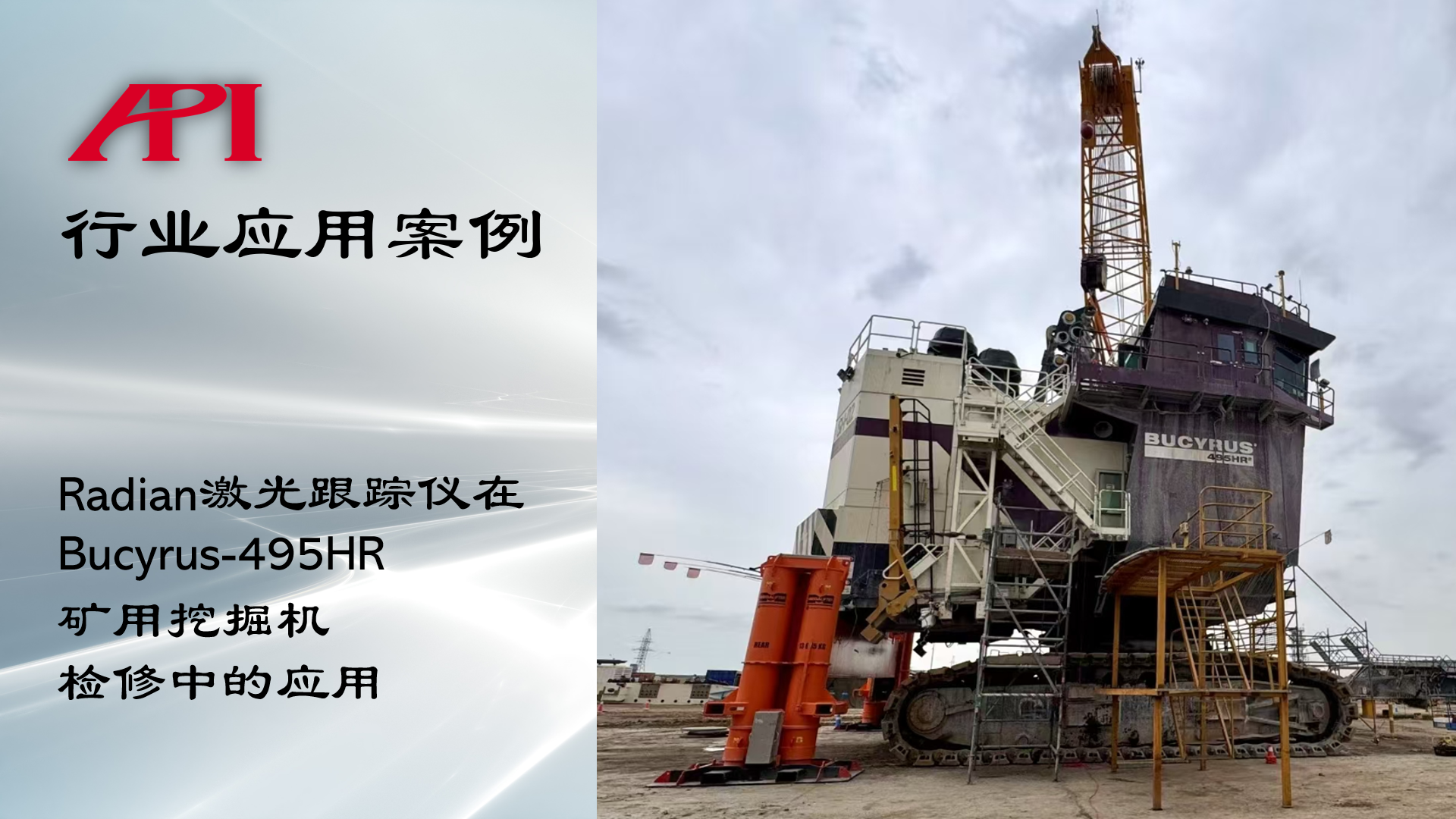

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

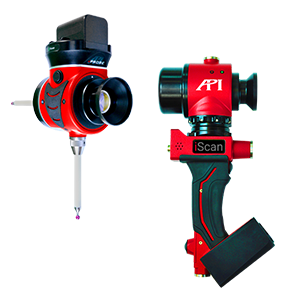

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858