Simulation platform & 3D dynamic measurement

For the manufacturing and research process of modern aircraft, spacecraft, vehicles, ships, etc., 6D dynamic simulation experiments have become indispensable items. Therefore, the dynamic posture index of the 6-pole platform used in 6D simulation has become a hard indicator to measure the simulation platform. In practical applications, mechanical, control and other factors will produce dynamic trajectory errors of the 6D platform. If the error is too large, the platform will not meet the expected accuracy requirements.

Among the many reasons for the error in the evaluation, the evaluation of the dynamic 3D spatial error is a very important one. This data needs to be measured in a dynamic and high-precision manner, which poses a challenge to traditional measurement methods, because it is difficult for traditional static measurement methods to measure effective dynamic 3D data. Therefore, finding a large-scale, high-precision, and dynamic digital measurement method has become a simulation platform to solve the problem.The key to detecting problems.

API laser tracker dynamic 3D accuracy detection solution

In order to solve the problem of accurate measurement of the dynamic 3D spatial position of the mechanism, API Company has developed a 3D point dynamic measurement target-ActiveTarget active target (as shown in Figure 1, hereinafter referred to as the AT target). The AT target is similar to the traditional tracker SMR target ball. The laser of the tracker is reflected back to the tracker through the mirror body to complete the spatial position measurement. The special feature is that the AT target has a drive motor in both horizontal and vertical directions, which has the ability to automatically locate the reflective target, which is equivalent to a motorized target.The SMR.

Figure 1: Radian laser tracker and ActiveTarget active target

In actual measurement operations, AT targets have the following advantages:

-No matter what orientation you are in in space and whether you are moving or not, the AT active target will always lock the laser beam. Even in fast and arbitrary movement measurements, the laser tracker will not lose the laser beam.;

-During the measurement process, the AT moving target can automatically track the target body in any rotational movement without manual human intervention, and complete the coordinate collection of the spatial 3D dynamic position.;

The emergence of the-AT target has made it easy to achieve high-precision dynamic 3D spatial position measurement of large-scale 5-axis/6-axis machine tools, robots, simulation platforms, mechanisms, etc.

Simulation platform 3D dynamic measurement requirements

For the measurement of the 3D dynamic data of the simulation platform, the simulation platform needs to be started and operated under the planned path, the position data under the dynamic trajectory is measured, and the calculation and analysis are carried out, and finally realized.:

1. Compare the measured dynamic point coordinates with the theoretical operation digital-analog trajectory, view its spatial error value, and obtain the maximum angular displacement error and the maximum linear displacement error.;

2. By measuring the change in distance between points and the angle change of the relative point to the center, and comparing with the time at the corresponding interval, the maximum linear velocity and angular velocity are obtained.;

3. Project the dynamic trajectory points in the three-phase limit plane to view the dynamic matching performance during the operation between the moving bodies.

Figure 2: Simulation platform inspection site: Radian laser tracker cooperates with ActiveTarget active targets to realize the 3D dynamic measurement of the simulation platform

(The picture on the left shows a panoramic view of the measurement site; the picture in the middle shows a close-up of the AT target; the picture on the right shows a schematic diagram of the movement direction of each mechanism of the simulation platform)

Actual measurement and goal achievement

During the actual measurement, you only need to set up the Radian laser tracker in a suitable position, and the laser is injected into the AT target fixed at the target end to start the measurement. The target end travels or moves along a given trajectory, and the Radian laser tracker performs dynamic measurements at a sampling rate of 1000 points per second, and transmits the data to the measurement software in real time for recording, for real-time or subsequent calculation and analysis.

Throughout the measurement process, the AT target always faces the laser tracker in the best attitude and locks the laser beam, automatically adjusting the attitude without manual intervention to ensure the smooth and efficient measurement.

ActiveTarget active target adopts a highly integrated design, compact size, the whole machine weighs only 0.9 kg, has extremely high optical centering accuracy, and can achieve unlimited rotation of 360° in the horizontal direction, which is convenient to be stuck at the end of the target to be tested in any attitude, providing the greatest measurement operation.Convenient; At the same time, its battery-powered working mode completely gets rid of the shackles of cables, and the battery life of more than 16 hours in a conventional environment provides a strong guarantee for the smoothness of the entire measurement operation.

Figure 3: ActiveTarget activity target

conclusion

In summary, the API brand Radian tracker cooperates with ActiveTarget active targets, and the entire system is easy to install, fast, and simple to operate. As long as the tracker and AT active targets are installed in a few simple steps, the dynamic 3D trajectory measurement of the simulation platform can be solved, laying a good foundation for improving the performance of the simulator as a whole.The foundation of.

Figure 4: API company headquarters Building

About API

The American Automatic Precision Engineering Company (API Company) was founded by Dr. Liu Jinchao in 1987 on the basis of independent patented technology and is headquartered in Rockwell City, Maryland, USA. Since its establishment, API Company has always been committed to the research and development and production of precision measuring instruments and high-performance sensors in the field of machinery manufacturing. Its products have been widely used in advanced manufacturing fields in the United States and other countries around the world, and it is in a leading position in the high-precision standards of coordinate measurement and machine tool performance testing. API company has an experienced and capable team of engineers, and constantly develops advanced and innovative products to meet the needs of rapidly developing industrial technology. In many projects of the U.S. federal government, enterprises, and scientific research, API companies are active participants and key technology partners. The achievements made so far have made it enjoy a high reputation in the field of international precision measurement.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

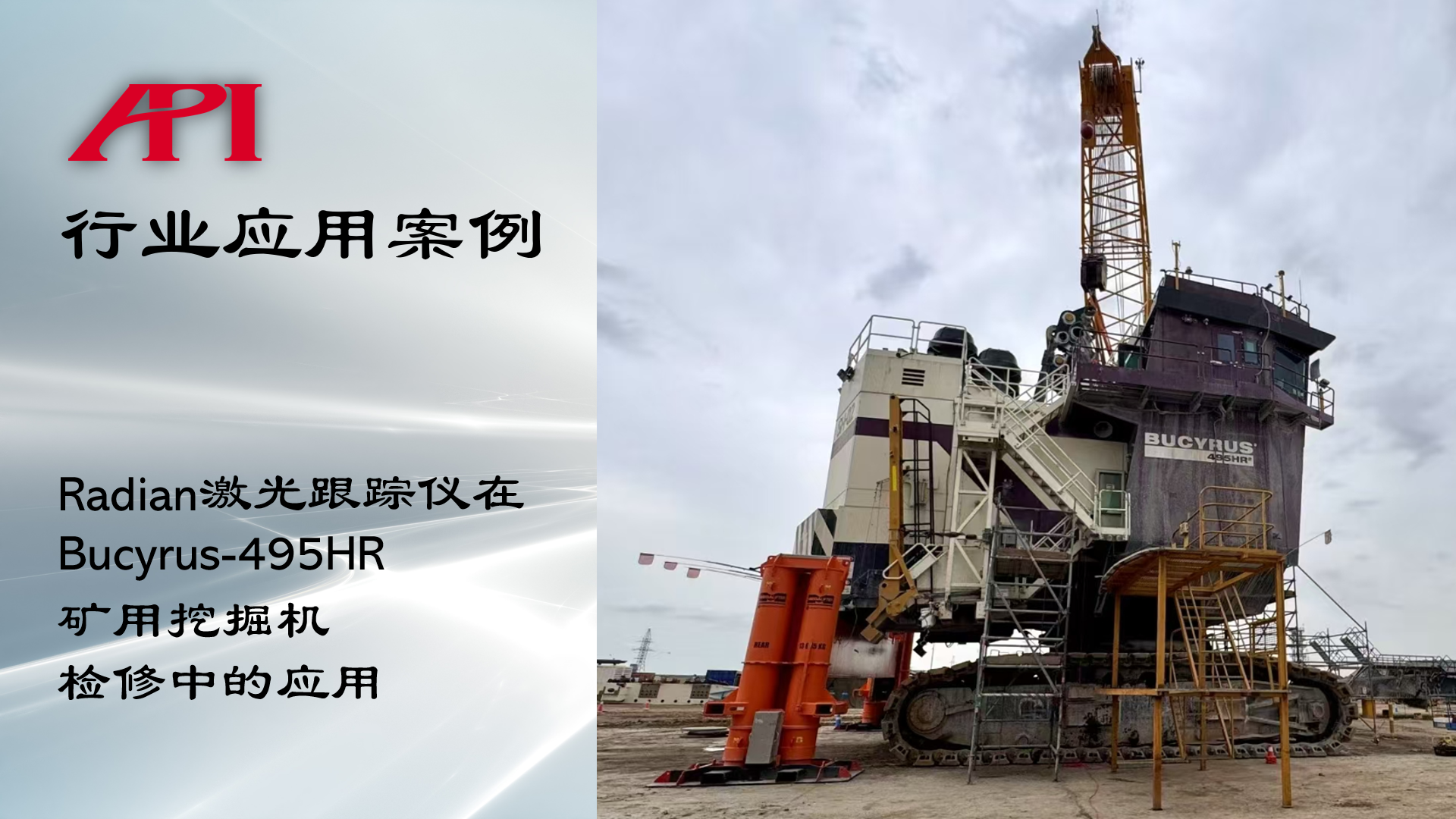

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

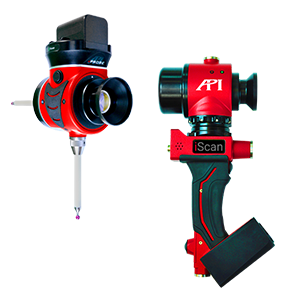

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858