A high-tech enterprise in Suzhou has been supplying all kinds of large box parts to various famous companies for a long time.

Challenges and requirements

1. Oversize measurement: Coaxiality inspection of large box parts, including all the characteristics of the shape and position tolerance. It is not possible to inspect on the three coordinates. Dimensional control during processing, and measurement report after the completion of the workpiece processing;

2. Accuracy requirements: coaxiality requirements with an accuracy of 0.1mm, the distance between the two axes, and the accuracy of the diameter of each cylindrical hole;

3. environmental complexity: the presence of vibrations in the workshop, unstable temperatures in the machine tool machining room leading to variations in accuracy;

4. inspection of the process control link during rough machining.

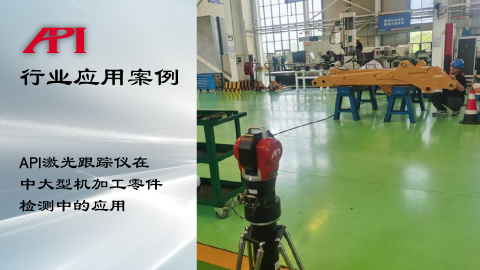

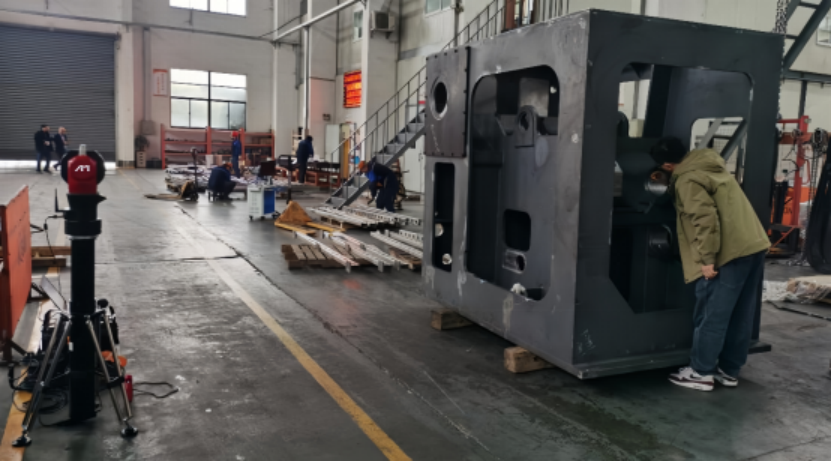

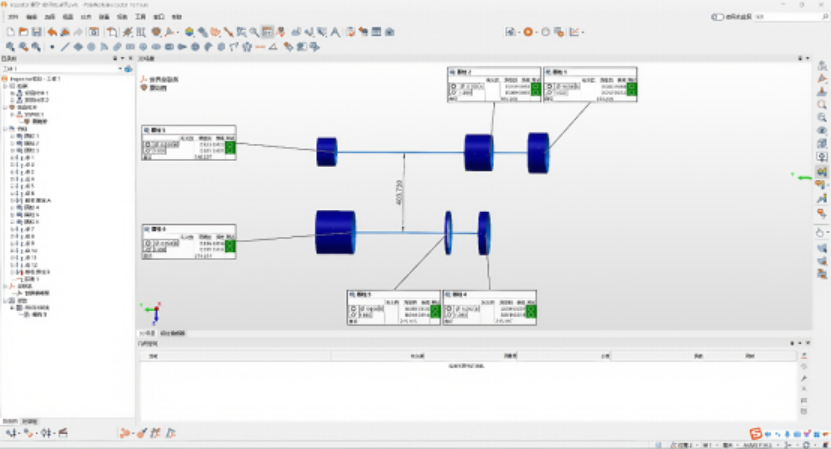

Figure 1: The measurement site, the layout of the tracker station

Solution

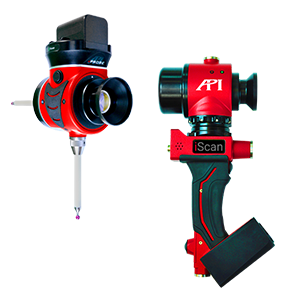

utilizes the API Radian Core laser tracker, configuration options include:

- Highly accurate static measurements: micron-level measurement accuracy guaranteed;

- Temperature compensation module: built-in sensor automatically corrects for the effects of ambient temperature and humidity;

- Portable design: Lightweight and compact, the device weighs less than 11kg, and can be quickly deployed in assembly stations.

Figure 2: API branded laser trackers of various models

Figure 3: Model used in this case - Radian Core Laser Tracker

Function and Embodiment

1. in this case, the Polyworks software is used in conjunction with the tracker to measure and obtain the data of each feature, and analyze it to obtain the coaxiality accuracy of the part;

2. automated reporting: the Polyworks software generates a quick report to get the report that the end customer needs;

3. Extended compatibility: by setting up the equipment in a fixed position and fixing the tooling to the part, rapid inspection of the same type of part can be realized, thus improving the generation efficiency.

Figure 4: Measurement site in this case

Figure 5: Measurement data and analysis

Figure 6: Measurement report

Summarize

The application of Radian laser tracker has solved: ① the customer's precision control inspection of on-line rough machining of parts; ② the customer's inability to measure the axis distance as well as the parallelism of the two axes and the coaxiality of the two ends of the inspection; ③ the customer's problem of the change of the environment at its site by the influence of temperature.

Customer Testimonials

API solution has shortened the cycle time of parts inspection and realized the digital inspection of the whole machine. Its equipment can be on the machine tool online inspection of parts and advance process control capabilities, for the environmental requirements have a strong adaptability, to meet the temperature on the machine, off the machine after another temperature of high-precision inspection.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

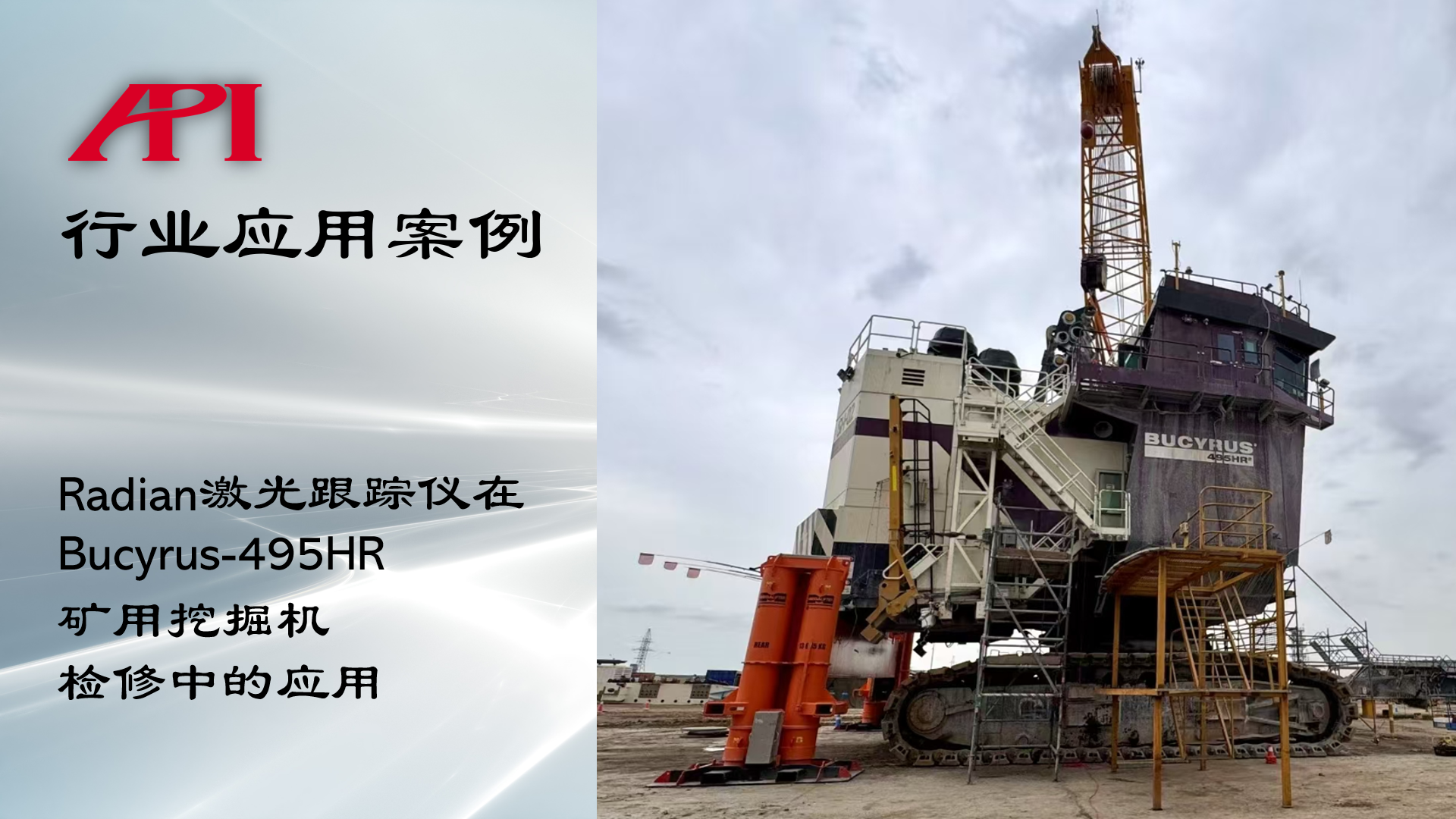

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

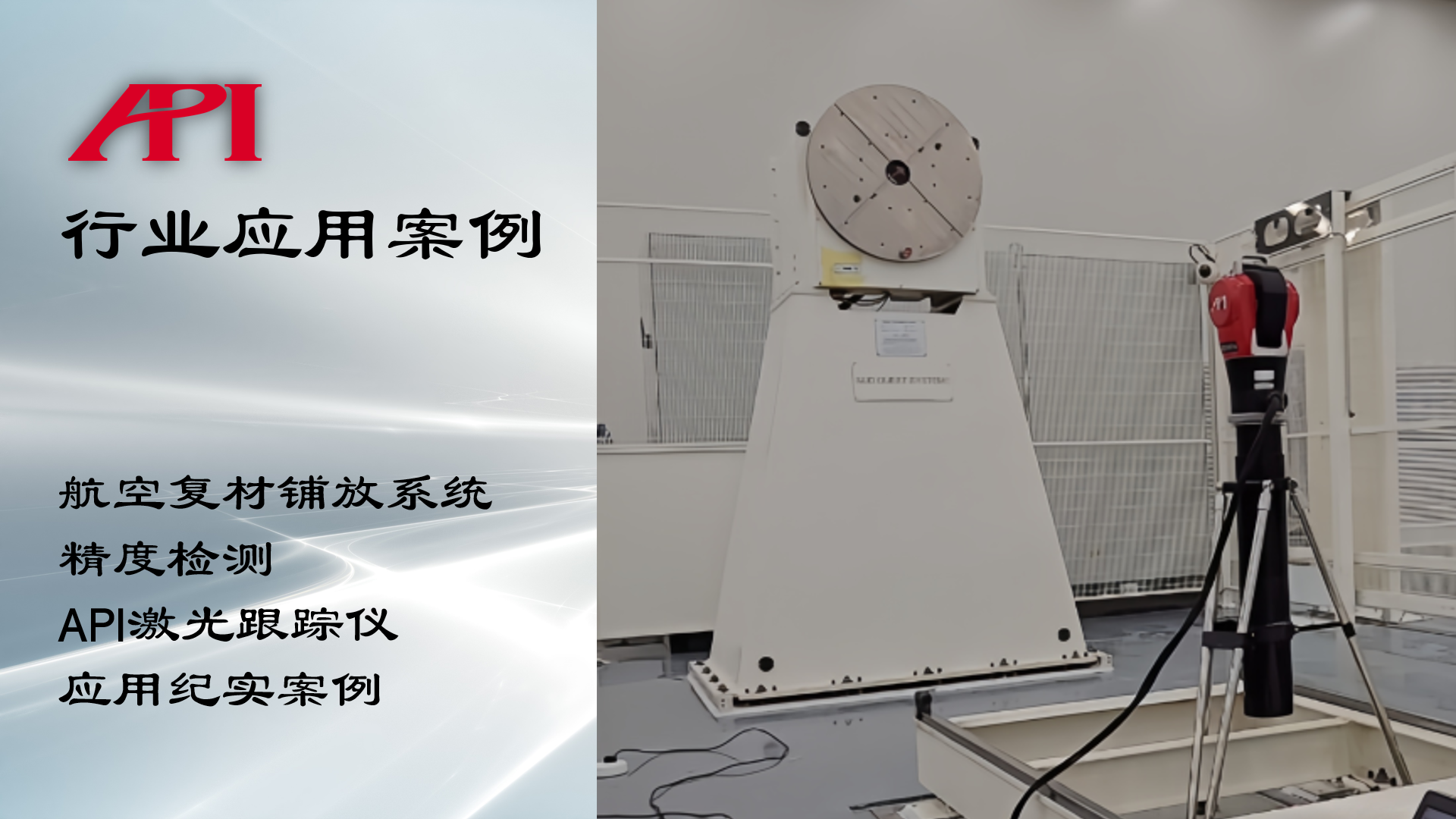

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858