Background

A large paper enterprise decided to carry out systematic accuracy calibration of its large paper machine to solve the problems of paper wrinkling and uneven thickness that occurred in the operation of high-speed paper machine, and at the same time, the manufacturing requirements of new products put forward a higher demand for equipment accuracy.

Inspection Difficulties and Challenges

In the measurement and inspection operations for large paper machines, traditional optical instruments and mechanical gauges are limited by the measurement range, accuracy and dynamic capacity, making it difficult to efficiently complete the comprehensive verification and adjustment of the geometric accuracy of the machine. In the implementation of measurement and inspection operations, the main challenges are: ① oversized structure - drying cylinder group length of more than 30 meters, the traditional tools are difficult to measure the overall coaxiality and parallelism; ② dynamic accuracy measurement needs - need to assess the roll in the simulation of operating conditions (such as micro-vibration, thermal expansion) under the measurement of form and positional tolerance; ③ ultra-high-precision 3D measurement requirements - coaxiality, roll surface runout, the bearing mounting surface (iii) Ultra-high precision 3D measurement requirements - coaxiality, roll runout, bearing seat mounting surface flatness, etc. are all critical parts of the equipment and require high inspection accuracy; (iv) Reduced downtime and the most efficient way to complete the inspection and adjustment - the high cost of daily downtime on the production line requires efficient completion of the measurement and calibration work.

API Solution

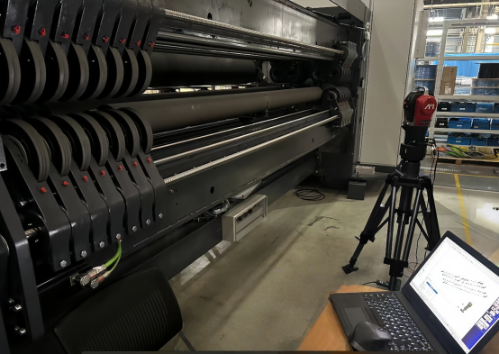

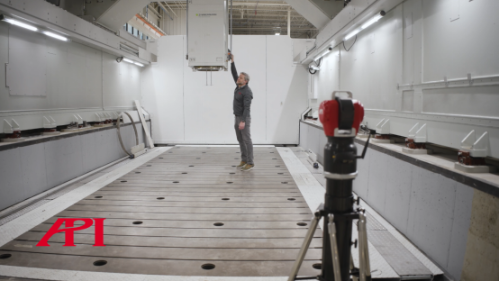

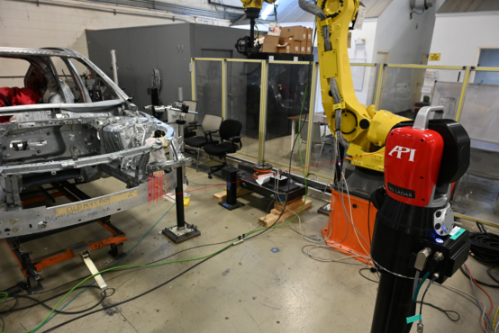

In response to the needs and difficulties of paper machinery measurement, API provides the Radian Plus laser tracker for this measurement to realize the relevant measurement needs. The Radian Plus laser tracker is portable, accurate, large range and high efficiency, which can provide micron-level 3D measurement accuracy, and its ultra-high picking rate of 1,000Hz ensures its excellent performance in both static and dynamic measurement needs. With a measuring range of more than 160 meters, the Radian Plus laser tracker can solve the needs of paper machinery for measuring over a wide range of tens of meters. In addition, Radian Plus laser tracker adopts battery power supply system and wireless data transmission module, which can realize completely wireless precision measurement operation, fearless of complex measurement site environment and narrow space, simple operation and easy to use.

Measurement Contents

In the case, a Radian Plus laser tracker was used to measure and evaluate the following: (1) coaxiality and parallelism of the press rolls, guide rolls, and drying cylinders; (2) flatness and horizontality of the mounting base surface of the bearing housing; (3) round runout of the end face of the drying cylinders and straightness of the roll surface busbars; and (4) symmetry and perpendicularity of the machine frame.

Measurement and operation process

1, laser tracker deployment: set up a laser tracker at a suitable location around the paper machine to be measured, to ensure that all the components to be measured through the position;

2, establish the coordinate system: in the measurement software to establish a global measurement coordinate system;

3, static measurement: the use of 1.5 inches of high-precision SMR target ball, with the various types of pins, seats, and rapid acquisition of the center of the hole in the coordinates of the various bearing housings, measurement of the end face of the drying cylinders, Roller surface key cross-section circumferential points, as well as scanning the important mounting plane of the frame;

4, dynamic measurement simulation operation verification: in the low-speed state, tracking and measurement of the key roller radial runout and axial runout; acquisition of drying cylinders in the process of temperature rise of the key point coordinates of the change, to achieve the impact of the thermal deformation caused by the evaluation of the operation process;

5, data analysis and adjustment guidance: through the measurement of the collected data, using the measurement software, to obtain the coaxiality of each roller according to the demand. According to the demand, get the coaxiality error, parallelism deviation, flatness error, round runout, etc. of each roll; generate intuitive deviation report and detailed data list; then use the measurement report as data support to guide the on-site adjustment, and accurately correct the deviation by adding or subtracting the bearing seat shims, and fine-tuning the position of the rack.

Summary

Radian Plus laser tracker, with its micron-level measurement accuracy, large measurement range, and excellent performance in dynamic/static conditions, fully meets the needs of large paper machinery shafts, rolls, drying cylinders, racks, and other critical position measurement. After calibrating with the Radian Plus laser tracker, the coaxiality of the key rolls of the paper machine, the flatness of the mounting base surface, and the runout error of the dynamic measurement in operation have all reached the design standard, and the measurement operation which took several days with the traditional measurement method was completed in a very short time, which significantly improved the working efficiency and saved time and cost for the enterprise.

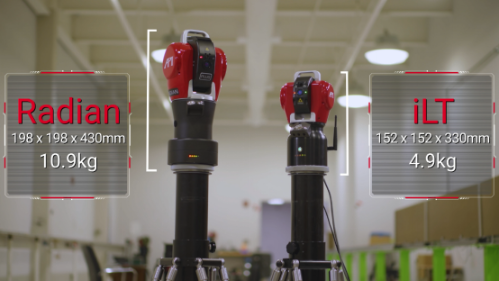

Break through the extreme, more choices

In addition to the Radian model laser tracker used in this case, the API brand also launched a new iLT laser tracker. On the basis of the Radian Plus/Core model, which can achieve complete wireless measurement, the overall size of the laser tracker is further reduced by 50% (compared to the Radian series), and the whole machineWith a weight of only 4.9kg, it maximizes the portable properties, fully satisfies and is suitable for outdoor, outdoor, small spaces, multi-machine integration and other application environments.

Leading the Future, More Expansion

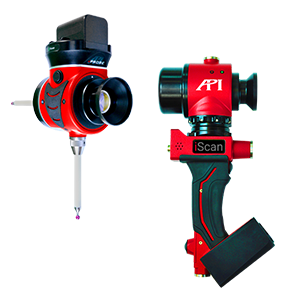

In addition, API brand 9D LADAR products can realize non-contact measurement without cooperating with the target on the basis of high measurement accuracy at the micron level. Based on OFCI core measurement technology, the spatial coordinate data of the laser touching position can be fed back to the measurement software in real time to record the data, and the data acquisition rate is as high as 20KHz, which instantly realizes point cloud The data acquisition rate is up to 20KHz, instantly realizing the point cloud data acquisition, accurate, fast and efficient.

+86 10 59796858

+86 10 59796858