Exploration in the Measurement Field of Wind Turbine Tower

The wind turbine tower is the most important core component in the construction of the wind turbine support part: it has complex characteristics such as long dimensions, small width, and easily deformed features due to welding parts, which are prone to cause deformation factors such as parallelism, flatness, perpendicularity, hole position, and angle of the tower frame.

In the process of work, as it is directly used for supporting, the design of the tower frame requires high control over material, size processing accuracy, welding technology, and installation positioning assembly, so manufacturing and quality inspection are crucial in the production process of the tower frame. With the continuous improvement, updating, and refinement of handling equipment in our country, the characteristics of products gradually becoming larger, higher, more refined, and more stable, the current detection methods relying on manual experience, bridge-type three-coordinate machines, articulated arms, etc., have gradually been unable to meet the high precision and high reliability requirements of large-scale generator tower frames in detection, and the demand for high-precision size detection technology in large spaces has become increasingly urgent.

In order to detect the processing accuracy of products and whether the assembly meets the design requirements, measurement is an indispensable and important link in the production and assembly process. The generator tower frame has very high requirements for the flatness, perpendicularity, and installation hole position and distance of the positioning plane, and at the same time, due to the deformation of the welded parts after stress release, it also poses great challenges to measurement and assembly technology.

Figure 1: A certain type of wind turbine tower frame

Traditional Measurement Methods

Currently, for the measurement of generator tower frames, customers mainly use articulated arms in conjunction with gauges for detection. The articulated arm can detect local dimensions and spatial dimensions of the product. Due to the limitations of the measurement capability of the articulated arm itself and the errors caused by the station factors, it is difficult to achieve the measurement results required by the customer. Large-scale bridge-type three-coordinate machines can carry out high-precision size detection, but due to the limitations of the large size and height of the product, and the inability to detect the actual usage angle of the tower frame, they have already been unable to meet the overall detection requirements of large-scale components. Large calipers cannot meet the limitations of distance detection above 3 meters and the inability to measure parallelism and position, and the measurement requires the cooperation of multiple people to complete, which greatly increases the accuracy requirements of the measurement method and force, and it is difficult to control the stability and repeatability, which is prone to deviation. It greatly consumes human and material resources.

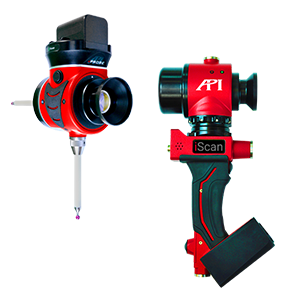

Figure 2: API brand series laser trackers (from left to right: Radian Plus/Radian Pro/Radian Core/iLT)

Laser Tracker Measurement Solution

Generator door frame manufacturing enterprises are actively seeking and urgently needing equipment that can quickly solve the stability detection of generator door frame flatness, angle, installation hole position, verticality, and other issues. By understanding the pain points and difficulties of customers, they are actively utilizing laser tracker technology to quickly detect customer products and obtain detection data, thereby achieving detection results such as parallelism, verticality, flatness of positioning planes, installation hole position, and installation plane angle of the generator door frame. For the detection of generator door frames, our company, based on the comprehensive application discussions and summaries of software and hardware engineers, not only improves the quality and stability of customer products but also provides more comprehensive assembly positioning guidance during the installation process and expands the application measurement of other customer products, providing strong data support. The following is a series of explorations into rapid measurement methods.

1. For the detection of parallelism, positioning assembly plane flatness and distance, verticality, and hole position of the generator door frame, the latest generation Radian Core model laser tracker from API company is used, combined with a high-precision reflective target ball SMR. Operators only need to hold the target ball to collect data of the measured plane and process the data in the background with the software, with the advantages of simplicity and ease of operation;

2. For the large and long characteristics of the generator door frame, a high-precision reflective target ball is used in conjunction with a turntable station for multi-directional turntable and software processing to detect flatness, verticality, hole position, and installation plane angle, which greatly saves the customer's detection time.

Figure 3: Measurement site of wind turbine generator door frame in this case

Measurement Process

One, Equipment Deployment

In this case, the application engineer uses a portable device tripod stand to set up the Radian laser tracker around the door frame to be measured, so that the laser can be visible to the target position.

Two, Data Collection

During data collection, the measurement engineer holds a target ball with an integrated prism at the measurement position of the component to be measured, and the Radian laser tracker master emits a laser and locks the center position of the SMR in real-time. When the target ball touches the measurement position, the spatial coordinate data of the position is rapidly collected at a measurement rate of 1000Hz and transmitted to the measurement software on the laptop for subsequent analysis.

Three, Data Analysis

Once the spatial coordinate data of all the points to be tested at the test locations have been collected, the corresponding points can be found in the measurement software. Use these points to construct lines, surfaces, volumes, and so on, set the tolerance range, compare with the ideal values, and obtain the deviation data, thereby achieving the purpose of measurement and detection.

Four, Analysis Report

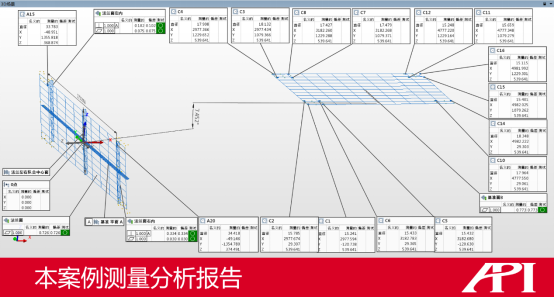

In the measurement software, you can filter and annotate the required report content, and automatically calculate and generate a measurement analysis report.

Figure 4: Measurement Analysis Report of This Case

Advantages & Features

1. The Radian series laser trackers from API brand are representative tools in the field of precision measurement. Laser tracker measurement technology has been widely used in high-end manufacturing and academic research in various industries.

2. The Radian series laser trackers are characterized by excellent performance, stable performance, extreme portability, and ease of operation. They are the perfect solution for large-scale precision measurement and represent the cutting-edge technology in laser tracker measurement.

3. The Radian Plus\Core laser tracker breaks through the traditional design concept of trackers, integrating controllers, temperature compensation systems, tilt sensors, and batteries internally. Its compact design fully meets the requirements for high-quality measurement tasks in limited measurement spaces.

4. In addition, the Radian Plus\Core laser tracker is integrated with an internal built-in Wifi wireless data transmission system, which greatly simplifies the installation process of the equipment and eliminates the troubles usually caused by wires/connections during equipment installation.

5. The Radian Plus\Core laser tracker uses an absolute laser ranging system to ensure measurement accuracy in high speed and convenience, and also supports the quick break and reconnect function to improve measurement efficiency. Its automatic target locking function allows the laser tracker to quickly and automatically find and lock the operation target ball in the event of a break in light, greatly facilitating the user's measurement.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

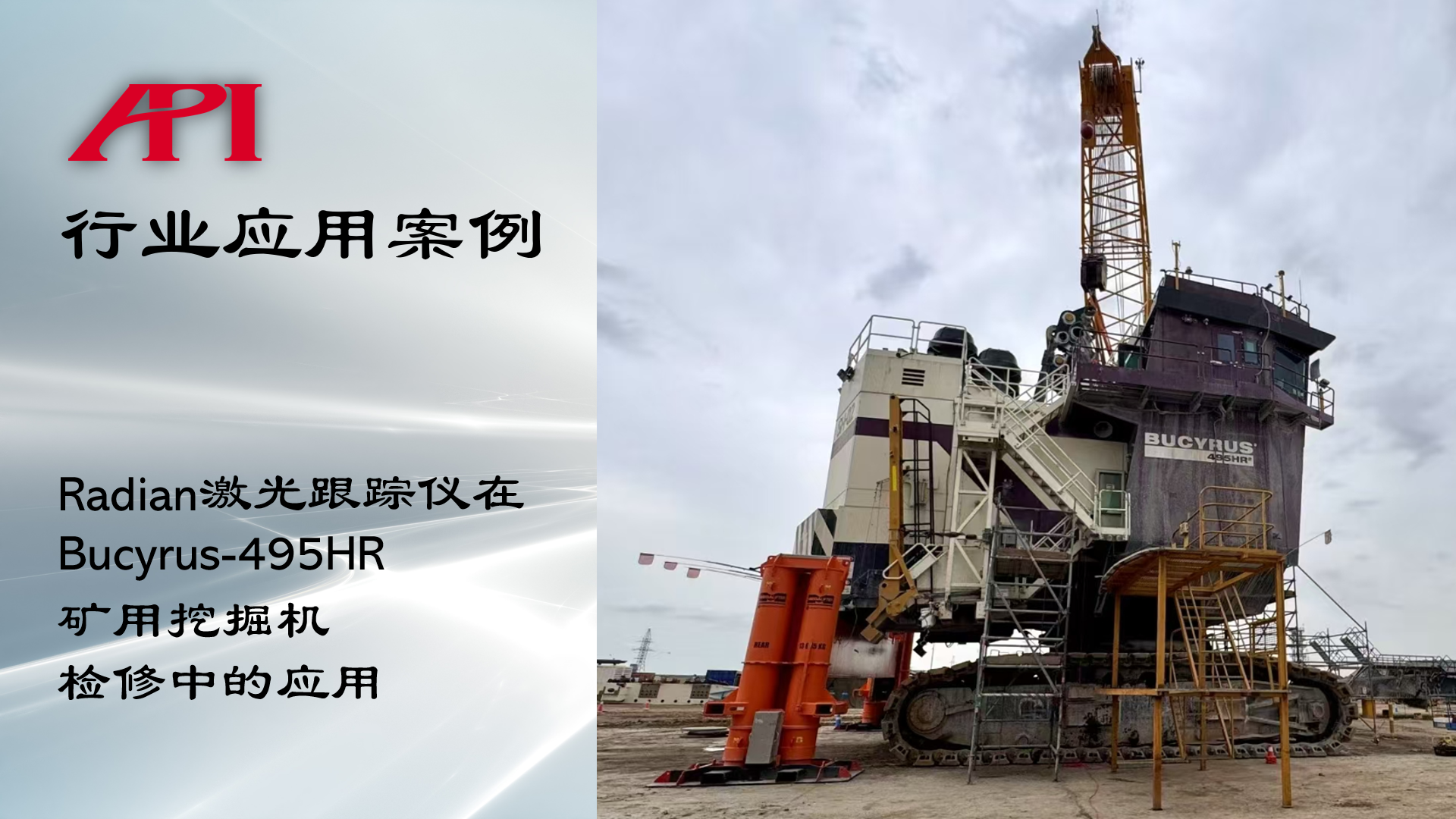

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

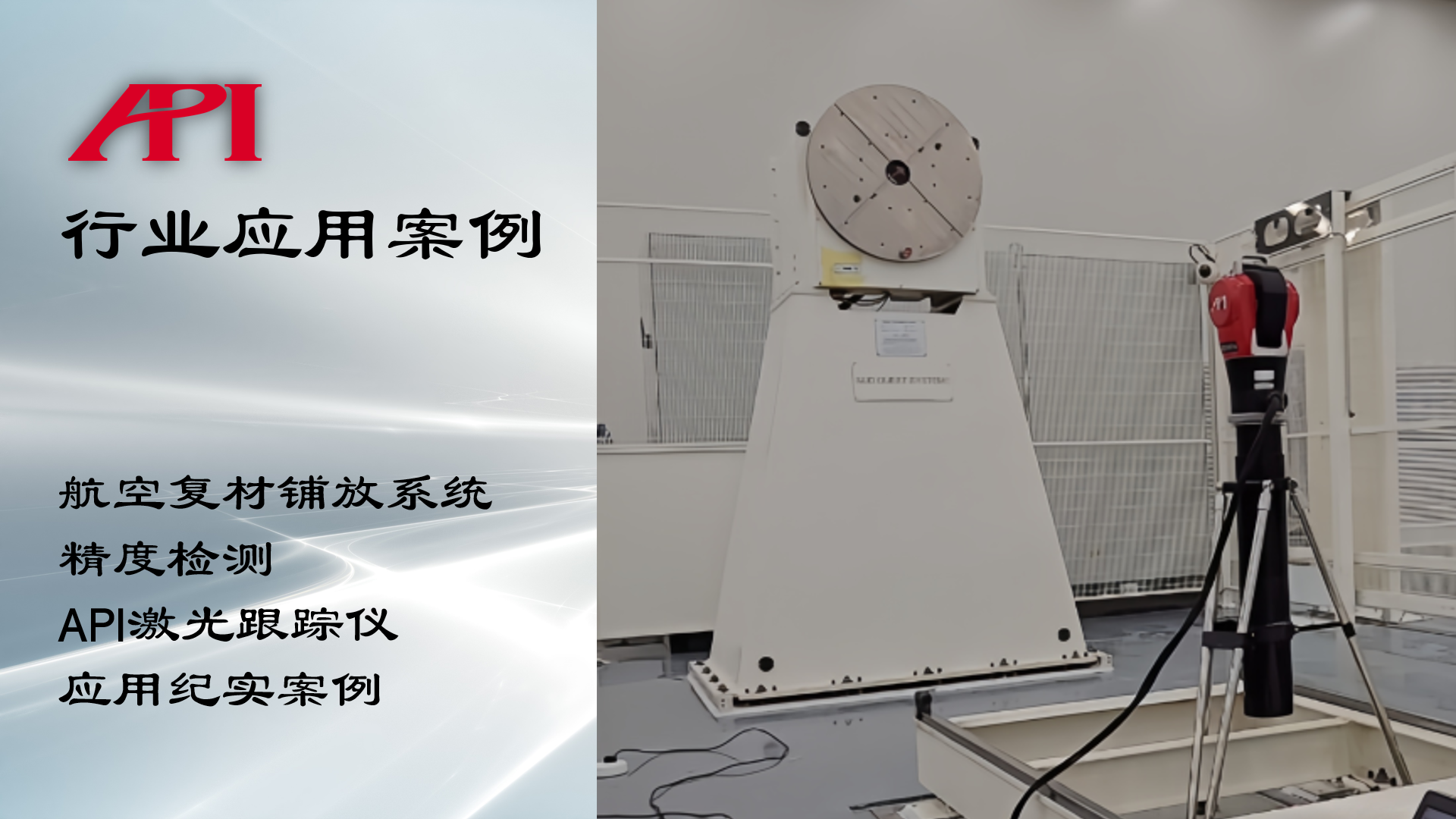

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858