10,000-ton-class Rotary Kiln

The rotary kiln, as a basic industrial equipment, has a history of over a hundred years. In the past 10 years, due to the requirements of laws and regulations in various parts of the world, as well as the enhancement of human environmental awareness, there have been more stringent requirements for the products processed by industrial rotary kilns, as well as pollution emissions and energy efficiency during the processing process. In order to meet these requirements, higher standards are required during the manufacturing and installation of the kiln, starting from every detail, making rational use of every resource, which contributes to the implementation of the goal and concept of human sustainable development.

In this case, the inspected rotary kiln reaches the 10,000-ton class and has a length of over 60 meters, which is quite large in size; how to ensure more accurate and efficient construction has become an important factor to consider in all aspects of the whole machine manufacturing and installation.

Inspection Requirements

Due to its large size, the construction plan for this 10,000-ton-class rotary kiln adopts a segmented processing and对接 installation method. That is, the 60-meter-long kiln body is divided into approximately 20-meter segments, with a total of 3 segments for manufacturing; during installation, these 3 segments are then joined together to form a whole. This construction method requires precise and consistent processing accuracy during both the segmented processing and the对接 installation steps to ensure that the overall performance of the equipment after installation meets the standard. The specific inspection requirements are as follows:

1. During segmented manufacturing, it is necessary to inspect the coaxiality of the center of the cylindrical structure at both ends, as well as the perpendicularity of both ends to the kiln body axis;

2. During the对接 installation, it is necessary to accurately inspect the coaxiality of the datum hole, and create a datum virtual axis, using the datum axis as a reference to guide and adjust the对接 installation work in real-time;

3. Throughout the measurement of the 60-meter-long total length, ensure that the comprehensive measurement error does not exceed 1.5mm.

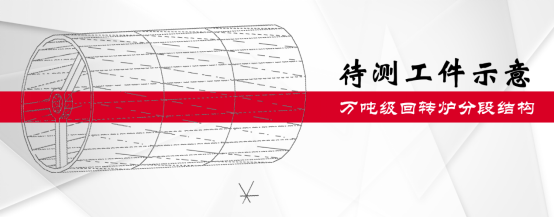

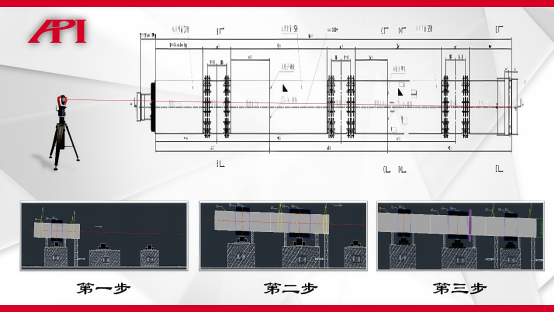

Figure 1: Schematic diagram of the segmented structure of a 100,000-tonne rotary furnace

Measurement Plan Analysis

A 100,000-tonne rotary reaction furnace is a super-large-scale multi-dimensional rotating workpiece, and its main technical indicators are closely related to its length. To meet these measurement requirements, the measuring equipment must have several functions at the same time:

Measurement range covers the size of the product;

Equipped with three-dimensional space measurement and data collection functions;

Can work efficiently within a limited measurement space;

Equipped with a powerful data processing system.

Currently, equipment capable of on-site measurement of large workpieces includes: theodolites, total stations, laser trackers, digital close-range industrial photography, and optical scanners, among others. Among them, theodolites and total stations can carry out large-scale measurement operations, but they have higher requirements for the working space, and the measurement is more dependent on the operator's own experience, with relatively large interference from human factors, and it is difficult to ensure good repeatability and efficiency; industrial photography and optical scanning are relatively efficient, but the measurement accuracy is limited by the influence of image stitching, and it is difficult to ensure high-precision measurement results within such a large range. After repeated comparison and verification by the manufacturer, it has been confirmed that using the API brand Radian laser tracker for the detection of the manufacturing and installation stages of the 100,000-tonne rotary reaction furnace is the best solution.

Figure 2: Radian Series Laser Tracker

Radian Series Laser Tracker

Radian series laser trackers are an excellent solution for large-scale precision measurement. They offer micrometer (μm) level measurement accuracy, with a measurement range exceeding 160 meters (radius 80 meters), and can be installed in confined spaces in various inclined positions. They are perfectly suited for precision measurement tasks of large-scale workpieces in various environments such as factories, outdoor sites, and testing bases. The entire process achieves automatic measurement and analysis of distance, angle, and other data, with minimal interference from human factors, ensuring the objectivity of the measurement data.

Actual measurement

1. Detection of part geometric tolerances in segmented manufacturing

Position the Radian laser tracker at an appropriate location around the part to be measured, and then start the measurement. During the measurement, the Radian will emit a laser beam and track the target ball (S-MR) in the operator's hand. The operator only needs to touch the target ball at the part to be measured, and the tracker can quickly collect the 3D data of the measurement point and record it in the software; after collecting a certain number of 3D data points in space, these points can be used in the software to construct lines, planes, and volumes, thereby realizing detection and analysis of the geometric tolerance data of the parts to be measured.

Figure 3: Schematic diagram of the steps for installation alignment and guidance adjustment of the rotating furnace

2. Real-time guidance during alignment installation

When aligning and installing segmented parts, it is possible to first create a reference axis based on the construction environment and use the real-time data feedback function of the Radian laser tracker to guide the operator to install each segment of the part in place and make fine adjustments based on real-time data until the position and attitude meet the standard.

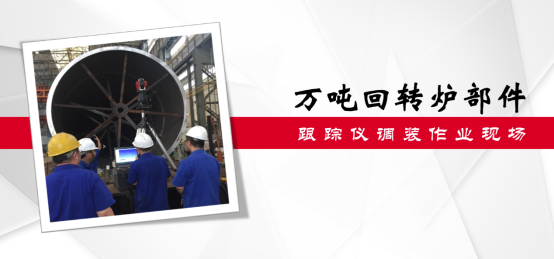

Figure 4: On-site operation of installing and aligning rotating furnace components using the Radian laser tracker

Summary

The micron-level measurement accuracy, large range and large-scale measurement capability, supplemented by flexible installation methods, make the Radian laser tracker a perfect detection tool for large-scale rotating reactors at all stages of manufacturing and installation, providing a reliable guarantee for the safe and efficient operation of the reactors.

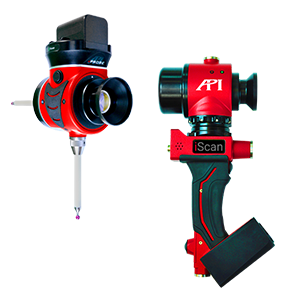

Figure 5: API series laser trackers (from left to right: Radian Plus, Radian Pro, Radian Core, iLT)

More Extensions

API has developed a variety of laser trackers in combination with practical application needs, including: (1) The Radian Core model laser tracker, which can achieve basic measurement functions and provides a more economical investment option for customers with relatively simple measurement complexity requirements; (2) The Radian Plus model laser tracker, which is a more functional and convenient laser tracker developed on the basis of a completely wireless intelligent measurement module; (3) The Radian Pro model laser tracker, which, while using high-precision ADM absolute laser, also integrates IFM interference laser (the standard for length measurement, traceable), providing a testing instrument that meets the needs of production and laboratory sites that have more stringent measurement accuracy requirements; (4) The iLT model, the latest sixth-generation laser tracker launched by the API brand, which, while having the basic functions of the Radian series, further reduces the overall size of the instrument to 152mm×152mm×330mm, with the main unit weighing less than 5kg, demonstrating great convenience and environmental adaptability in fields such as automated integration, laser tracker array operations, and portable measurement.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858