Necessity of Inspection for the Plane Carrier of Steel Bridge Body Joints

With the rapid development of China's bridge industry, the span of bridge bodies is becoming larger and larger, and the precision requirements for each section of the steel bridge carrier are also increasing. This is to ensure that after each section of the bridge body is joined together, it meets the overall construction requirements of the bridge, thereby ensuring the structural stability and bearing capacity of the bridge.

Figure 1: Radian Series Laser Tracker

Working Principle of Radian Laser Tracker

The Radain series laser trackers from the API brand are representative solutions for large-scale precision measurement. They consist of an advanced, compact tracking head (host), a target ball, a laptop computer, and software.

During measurement, the laser tracker emits a laser beam, which is reflected back to the tracker by the target. The tracker dynamically tracks the position of the target, and determines the position coordinates of the contact point by contacting the measured surface through the target.

Inside the host, the laser emits a laser beam, which is reflected back by the target ball, passes through a rotating mirror, and is split into two beams at the spectrometer. One beam enters the two-axis horizontal sensor, sensing the change in the target ball (movement), and thus transmitting the change to the controller and computer. The controller will guide the tracking head to make two angular movements (α and β). In this way, as the target ball moves, the tracking head and the target ball adjust their angles at any time to ensure that the tracking head tracks the target ball in real-time and records the X, Y, Z coordinates of the target ball's position.

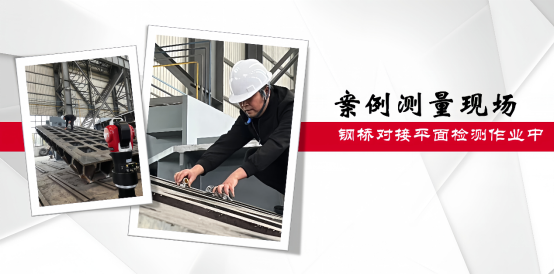

Tracker Detects the Plane of Steel Bridge Carrier

One of the important operations in the detection of the steel bridge carrier is the detection of the planarity of the bridge body joint plane. This work is carried out at the carrier polishing and welding site. The measured surface area is large, and due to the slope, there are certain difficulties in conventional operations, which can only be measured with a tracker. The operation is as follows:

1. Instrument Setup

Choose a suitable tracking instrument mounting position next to the measured carrier, set up the instrument, ensure that the instrument is securely installed, and calibrate it to ensure measurement accuracy.

2. Layout of the Global Coordinate System for Steel Bridge Carrier Measurement

Using the tracking instrument's basic coordinate system as the measurement basis, select typical measured points on the workpiece, and wipe the surface of the measured points with cotton to ensure that the measured points are free from oil stains and dust that could affect the measurement.

3. Measurement of the Carrier

The measurement personnel take a point on the surface of the steel bridge carrier at the measured points using the tracking instrument's target ball, thereby obtaining overall surface data.

Figure 2: Using the Radian laser tracking instrument during the detection of the steel bridge alignment plane

4. Data Analysis

Under professional measurement software, fit and analyze the measured data to obtain the surface flatness tolerance of the measured carrier.

Figure 3: Steel bridge alignment plane, flatness tolerance measurement report

Guidance for Repair

Based on the coordinates of the critical points on the surface being measured, the tracker can direct light to the critical points to guide workers in polishing corrections.

Tracker Measurement Benefit Analysis

Traditional measurements of steel bridge carriers are mostly combined measurements using leveling instruments and total stations, which are inefficient and difficult to ensure accuracy. Generally, it takes nearly a week of repeated measurements and adjustments for one carrier; however, after applying the API Radian laser tracker, the tracker's extremely convenient measurement methods and automated data analysis make the measurement and analysis time save over 80% compared to traditional methods; and with its ultra-high spatial measurement accuracy at the micron level (μm, 1/1000mm), it provides reliable accuracy assurance for measurement and maintenance operations, thereby winning more production time for bridge companies and significantly improving product quality.

Figure 4: API Series Laser Trackers (from left to right: Radian Plus, Radian Pro, Radian Core, iLT)

More Extensions

API brand, in line with actual application needs, has developed a variety of models of laser trackers, including: (1) The Radian Core model laser tracker, which can achieve basic measurement functions and provides a more economical investment option for customers with relatively simple measurement complexity requirements; (2) The Radian Plus model laser tracker, which is developed on the basis of a completely wireless intelligent measurement module and offers a more feature-rich and convenient laser tracker; (3) The Radian Pro model laser tracker, which, in addition to using high-precision ADM absolute laser, also integrates IFM interference laser (the standard for length measurement, traceable), providing the required testing equipment for production and laboratory sites that have more stringent measurement accuracy requirements; (4) The iLT model, the latest sixth-generation laser tracker from the API brand, which, in addition to having the basic functions of the Radian series, further reduces the overall size to 152mm×152mm×330mm, with the main unit weighing less than 5kg, demonstrating great convenience and environmental adaptability in automated integration, laser tracker array operations, and portable measurement.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858