Quick Production and Inspection of Clay Models

Creating clay models is a crucial step in the development process of new products and new designs for units or institutions involved in automotive styling and industrial design. Clay modeling technology is widely recognized as a method that can quickly, reliably, and accurately express design intent. This method uses a clay model milling machine to perform high-precision milling on materials such as clay, foam, and low-density wood based on digital control, quickly achieving the processing and inspection of the model.

A PI Comprehensive Solution for Clay Model Milling Machines

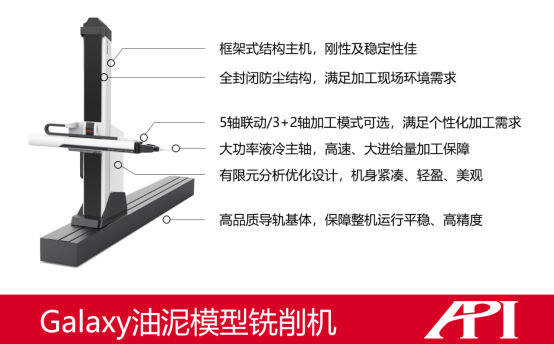

Building on over 35 years of technical expertise in 3D precision measurement, machine tool/robot calibration, high-precision machining, and high-performance sensors, the A PI brand has developed the Galaxy series of multi-functional clay model milling machines. These machines can fully and comprehensively meet the various needs of the industry for clay model processing, and provide high-quality and efficient guarantees.

Figure 1: A PI Galaxy Clay Model Milling Machine

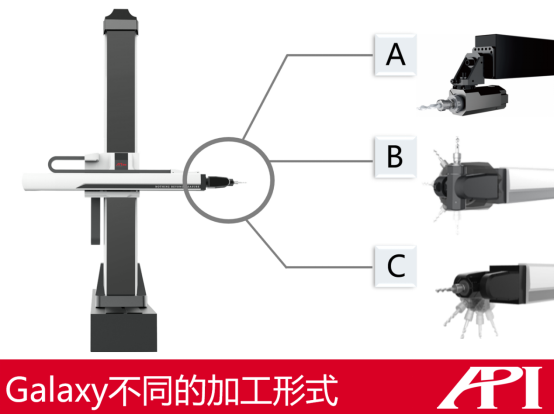

Flexible Selection of Machining Methods

The Galaxy series of clay model milling machines offers two types of machining methods: five-axis联动 and five-axis three-axis联动 (3+2 axes).

Among them, the five-axis联动 can achieve fully automatic machining of the X, Y, Z, A, and B axes: during the machining process, the machining head automatically swings, the tool always follows the normal direction of the surface being machined, and achieves continuous graduation rotation of the A and B axes, with excellent fit; it is only necessary to align the tool once to complete the subsequent processing continuously, with a smooth and uninterrupted machining process, providing the operator with a comfortable experience of fully automatic machining.

The five-axis three-axis联动 method (3+2 axes) provides the operator with a 1.5-degree graduation adjustment method for the A and B axes, which can be manually adjusted according to the processing needs, and realign the tool after adjustment, and then proceed with the machining; the 3+2 axis machining method is still efficient and provides the user with a more economical solution.

Figure 2: Galaxy Milling Cutter Form: 5-axis 3-axis (A); 5-axis联动/fully automatic dual swing head (B & C)

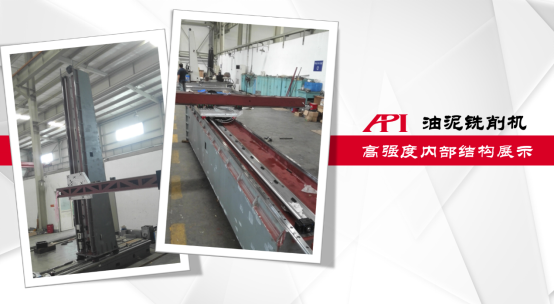

Heavy and light options available to meet different needs

The Galaxy series of oil clay model milling machines offers both heavy and light options, providing different solutions according to user processing requirements and on-site environment, fully satisfying the needs.

The heavy-duty milling machine is designed based on the frame structure of horizontal machining centers, with the bed body using a welded frame structure, high strength, large spindle power, and capable of high-speed, efficient processing of high-hardness materials. Typically, a 1:1 mold can be processed within 40 hours (one roughing pass, cutter spacing 15-18mm; one finishing pass, cutter spacing 3-5mm).

The light-duty milling system provides users with a frame-type compact main unit optimized by finite element analysis design, ensuring rigidity while making the main unit more agile and lightweight, fully adapting to various installation and usage environments, and meeting the needs of customers for installation on the second floor.

Figure 3: Internal structure display of Galaxy - High-strength welded frame-type bed body

Realize fast and accurate operations

Automatic tool setting function is provided for models with 5-axis 3-axis processing mode, improving tool setting efficiency and accuracy after changing different tools and tool positions. In practical applications, a lead tool setting is first performed, using the tool setter in an unknown position to determine the tool setter position; then, the automatic tool setting function is activated to determine the workpiece coordinate system, ensuring high precision in processing.

Each model can be configured with linear motor drive for the X-axis, precision ball screw drive for the Y-axis, and Z-axis, to the maximum extent ensuring the stability and speed, and acceleration of the main unit's movement, enhancing the overall movement performance and work efficiency.

Space error compensation ensures high processing accuracy

Galaxy's entire product line achieves significant system accuracy through 21+2 error compensation.

21+2-axis error compensation refers to the use of a proprietary spatial error compensation technology of the API, which compensates for the 6 position errors and mutual perpendicularity errors of the three-axis of the milling machine, as well as the deflection errors in the Y and Z directions of the cantilever three-coordinate system, thereby improving and ensuring the accuracy of spatial positioning.

Figure 4: Galaxy oil clay milling machine and marking machine co-rail installation and use

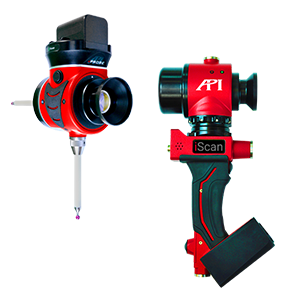

Figure 5: Galaxy oil clay milling machine equipped with scanner in application

Efficient Usage Methods

In practical applications, the Galaxy series of oil clay milling machines are flexible in installation and can be used in co-rail installation with marking machines, perfectly combining manual and automatic model making and modification functions (Figure 4); the Galaxy series of milling machines can also be equipped with a scanner system for rapid and accurate 3D data scanning and collection of the target, achieving multi-functional use with a single machine (Figure 5).

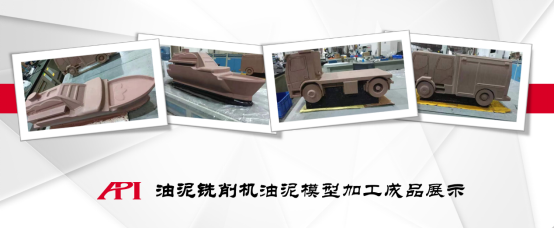

Application Examples

The following scene photos show the application of the Galaxy oil clay milling machine in an industrial design institution, utilizing the high precision, high processing strength, and efficient characteristics of the Galaxy to mill oil clay models such as yachts and vehicles:

Figure 6: Scene of yacht model milling processing

Figure 7: Scene of yacht model milling processing (multi-angle view)

Figure 8: Display of finished products of yachts and other processed models

Summary

The Galaxy series of clay model milling machines, with its superior product power, provides an efficient solution for the industry's clay model milling processing, and fully and comprehensively meets the various needs of the industry for clay model processing. It is the first choice equipment for processing clay, foam, wood substitute, and other material models.

Figure 9: A PI Company headquarters building

About API

Established in 1987, the American Automatic Precision Engineering Company (API Company) is headquartered in Rockville, Maryland, USA. Since its establishment, API Company has been committed to the research and production of precision measuring instruments and high-performance sensors in the field of mechanical manufacturing. Its products have been widely used in advanced manufacturing fields in the United States and various countries around the world, and it is in a leading position in high-precision standards for coordinate measurement and machine tool performance testing. API Company has a team of experienced and outstanding engineers who continuously develop advanced innovative products to meet the needs of rapidly developing industrial technology. API Company has been an active participant and key technical partner in many projects of the US federal government, enterprises, and scientific research. The achievements it has made so far have earned it a high reputation in the international precision measurement field.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

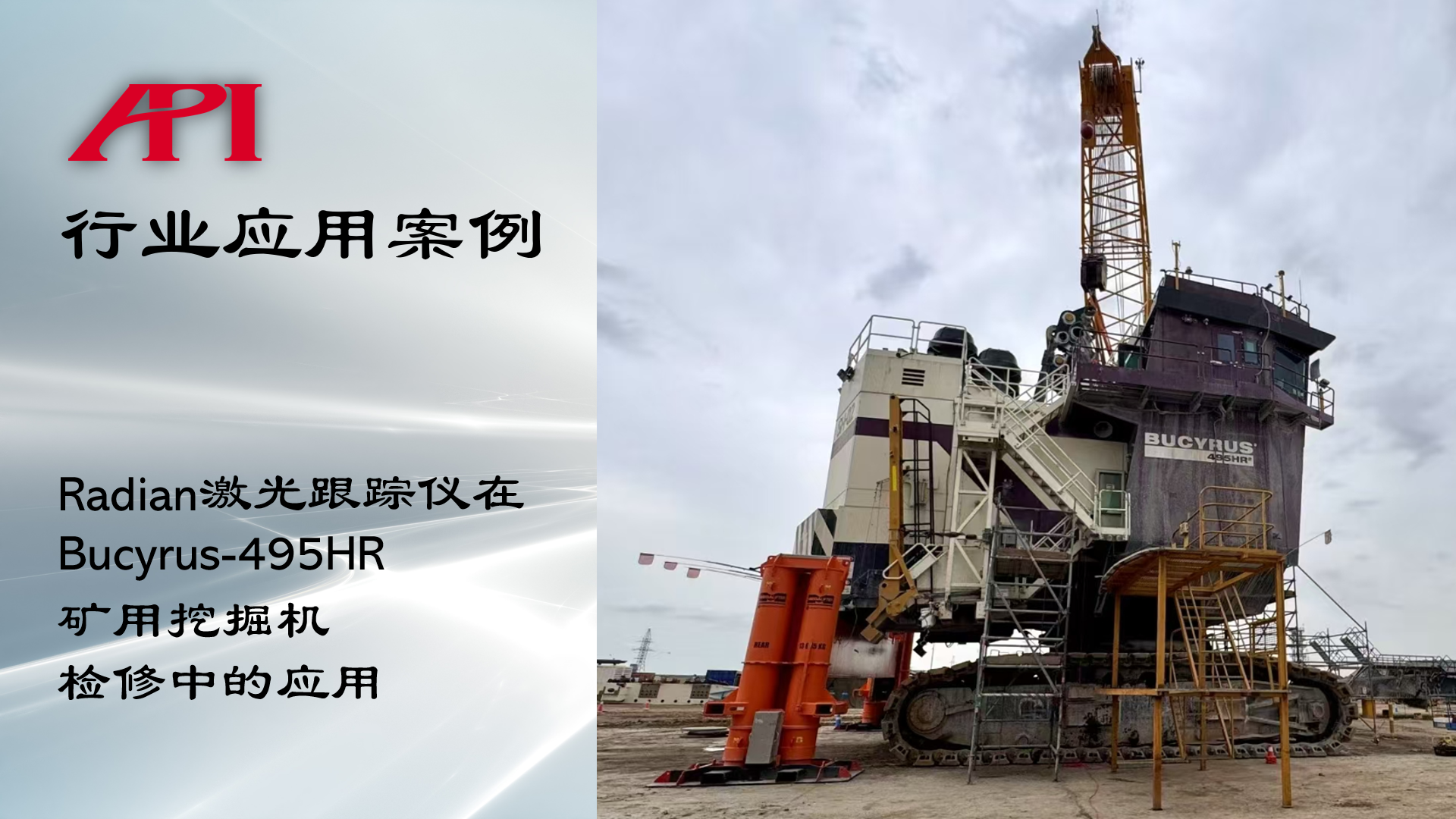

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858