Project Background

In this case, the large special equipment to be inspected is a cantilever structure large special equipment. The cantilever structure moves up and down in the vertical direction to the ground within a working range of 11 meters, realizing its functional use.

Measurement Requirements

Due to the structural reasons of the special equipment itself, the cantilever structure is prone to deflection deformation and motion direction guide rail straightness error during the lifting and lowering process. Therefore, after long-term use, it is necessary to carry out three-dimensional measurement, analyze the posture and operating status of the cantilever structure during movement, and ensure that all errors are within the required range.

Measurement Difficulties

Since the height of the special equipment is over ten meters, and the volume and weight of its moving mechanism are also relatively large, it is difficult to control the measurement accuracy and it is not easy to achieve data analysis if traditional measurement tools are used.

Figure 1: Measurement site of the special cantilever equipment to be measured in this case

API Solution

Based on the customer's requirements and comprehensive consideration of the measurement site environment, the API measurement engineer used the Radian Pro model laser tracker to perform the measurement task.

Figure 2: Radian Pro Laser Tracker

The Radian Pro laser tracker is the most precise laser tracker in the API laser tracker family, integrating IFM and ADM dual lasers. The IFM laser is internationally recognized as the standard for length measurement, and its measurement data can be traced back. The iVision active vision function of the Radian Pro laser tracker can also support path programming settings, assist in the automated target ball search and measurement, and perfectly match the detection requirements of this measurement task.

Measurement Preparation

Firstly, the API measurement engineer set up the Radian Pro laser tracker at a suitable position from the equipment to be measured, and set up measurement points at three positions of the cantilever structure of the equipment, and fixed three target balls on the cantilever structure with the help of the plane base.

Subsequently, the API engineer programmed the measurement path of the laser tracker according to the speed of the cantilever structure movement and the stopping position, and then the measurement could begin.

Figure 3: Measurement of the cantilever mechanism at different positions (red circles indicate the position of the target balls)

Measurement Implementation

During the measurement, the cantilever structure moves along the set direction and distance, and after it stops, the Radian Pro laser tracker automatically shoots the laser into the center of the three target balls set up according to the program for measurement. After the measurement of the three points is completed, the cantilever mechanism continues to move to the next position according to the established program for measurement. This process is repeated, and after the measurement of all the points at the stopping positions of the cantilever mechanism is completed, the collection of field data is finished.

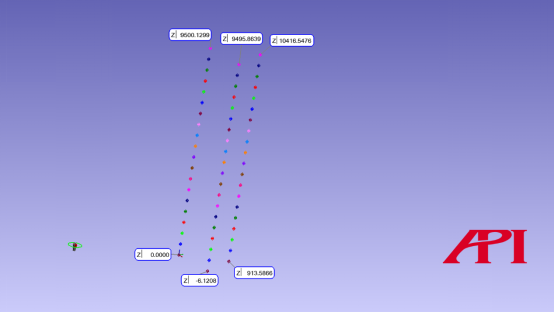

Data Analysis

By measuring 3 points at each stable position of the cantilever mechanism, the spatial coordinates and angular data can be integrated to calculate and analyze the posture data of the cantilever mechanism at the stopping position, thereby assessing its operating state.

Figure 4: Measurement Data

Customer Evaluation

The API laser tracker has provided us with a fully digital measurement and detection solution, making the inspection of large special equipment easier and more achievable, and the data analysis process is extremely smooth, saving us a lot of manpower, material resources, and time costs.

Figure 5: API Laser Tracker Family (Models from left to right: iLT, Radian Plus, Radian Pro, Radian Core, iLTx)

More Extensions

In addition to the Radian Pro model laser tracker used in this case, the API laser tracker family has many other members, each with different performance characteristics, providing a comprehensive solution for on-site measurement.

The Radian Core laser tracker can achieve fully wireless large-scale precision measurement, with a compact design, using the ADM Maxx laser, no need for preheating, and equipped with wireless data transmission and battery-powered systems, it can be flexibly installed in any position in a small and compact factory environment, avoiding the束缚 of cables, providing the greatest convenience for measurement operations.

The Radian Plus laser tracker, on the basis of the Radian Core model, further realizes the 6DoF measurement function, and can be compatible with more functional expansion accessories, such as the vProbe intelligent probe (for deep holes and hidden point measurement) and the iScan3D intelligent probe (for line laser scanning measurement).

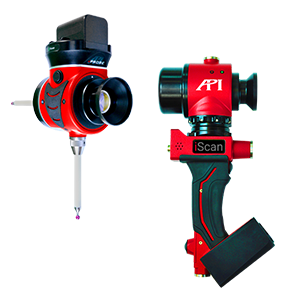

Figure 6: API Laser Tracker Functional Expansion Accessories

The latest generation iLT and iLTx laser trackers further reduce the body size and significantly reduce the weight, based on the already compact body size of the Radian series, making them perform even better in terms of portability and large-scale automation integration.

Please contact API's various representative offices in China. API's professional measurement engineers will develop a customized measurement plan for you based on your project requirements.

Figure 7: API Company Headquarters

About API

The API brand was founded by Dr. Kam Lau in 1987 in Rockville, Maryland, USA, as the inventor of the laser tracker, holding multiple patents for leading global measurement technologies, and leading in the field of precision measurement technology. Since its establishment, API has been committed to the research, development, and production of precision measurement instruments and high-performance sensors in the field of mechanical manufacturing. The products have been widely used in advanced manufacturing fields in various countries around the world and are at the forefront of high-precision standards in coordinate measurement and machine tool performance testing.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858