About Parallel Machine Tools

In recent years, the parallel machine tool products from various renowned manufacturers have shone brightly at globally recognized machine tool exhibitions such as EMO and IMTS. Their multi-degree-of-freedom motion characteristics, combined with the ability to adapt to high-intensity processing, have attracted attention and favor from visitors in high-end manufacturing industries. So, how are such high-precision, multi-degree-of-freedom parallel machine tools subjected to accuracy testing and calibration? The application of the API laser tracker has become a key part of the solution.

Parallel machine tools, also known as parallel structure machine tools or virtual axis machine tools, are products that combine parallel robot technology with modern CNC machine tools. They are high-tech products that integrate spatial mechanism theory, mechanical manufacturing, CNC technology, computer software and hardware technology, and CAD/CAM technology.

The characteristics of parallel machine tools include: the ability to achieve multi-coordinate linked CNC processing, assembly, and measurement functions, which can better meet the processing of complex special parts. They also balance many characteristics of both machine tools and robots, providing the flexibility and adaptability of robots while maintaining the rigidity and precision of machine tools. They are modern industrial equipment that integrates multiple functions, overcoming issues such as the fixed feed along a guide rail in traditional serial machine tools, low degrees of freedom in tool operation, and insufficient processing flexibility and mobility of equipment.

Based on the above characteristics, parallel machine tools are very suitable for processing complex free-form surfaces in fields such as aerospace and automotive manufacturing, such as impellers, blades, propellers, molds, and engine casings.

Compared to traditional serial machine tools, parallel machine tools have a relatively simple structure, but the motion of the entire platform involves a considerable amount of mathematical calculations, making it a knowledge-intensive mechanism. Therefore, to ensure better processing results, the calibration of the parallel machine tool itself, as well as the unification of the machine tool and workpiece processing coordinate systems, becomes a very important link.

Figure 1: API Laser Tracker Measurement Operation Site for Parallel Machine Tools

Further Enhancement of High Precision

In response to the working characteristics of parallel machine tools and the demands of typical application fields, API has developed a complete solution for improving processing accuracy for users of parallel machine tools.

1. Calibration, verification, and accuracy enhancement of the parallel machine tool itself.

Based on API's patented VEC (Volumetric Error Compensation) spatial error compensation technology, the Radian laser tracker is used to accurately collect the spatial coordinates of key points within the motion workspace of the parallel machine tool, and these coordinates are subjected to automatic data analysis and standard value comparison in specialized software to obtain errors and generate compensation parameters, which are then applied to correct the errors of the parallel machine tool.

Practical experience has shown that after measurement and calibration with the Radian laser tracker, the machine tool's accuracy can be improved by more than four times.

Figure 2: Using the API Radian laser tracker to achieve a high degree of unification between the coordinate systems of the parallel machine tool and the workpiece (top left: reference points on the parallel machine tool; bottom left: reference points on the workpiece)

2. High degree of unification between the workpiece and the machine tool coordinate systems.

Reference points are set on both the workpiece and the machine tool body, and the Radian laser tracker is used for high-precision measurement of these reference points (as shown in the above figure); after measurement, the actual positions of the workpiece and the machine tool relative to each other can be determined, and fitting can be implemented based on these positional parameters to achieve a high degree of unification between the workpiece and the machine tool coordinate systems, ensuring high-precision processing.

Figure 3: API brand series laser trackers (from left to right: models: iLT / Radian Plus / Radian Pro / Radian Core / iLTx)

API brand series laser trackers

The laser tracker, invented by API, is an excellent solution suitable for large-size dynamic/static, 3D/6D precision measurement.

The Radian series laser trackers are a range of laser tracking measurement technology products developed based on the A PI company's INNOVO measurement technology platform. They are characterized by high precision, good stability, flexibility, portability, and efficient human-machine interaction. The series includes three models: Pro, Plus, and Core. The Pro model integrates IFM (Interferometric Laser, a standard for length measurement, traceable) and ADM dual lasers; the Plus and Core models are powered by batteries and feature wireless data transmission, enabling completely wireless precision measurement.

The iLT series laser tracker is the sixth generation laser tracker developed by API. It is smaller and lighter than the Radian series, with a total weight of no more than 5 kg, making it an ideal 3D measurement device for production line integration and portable outdoor measurement tasks.

API laser trackers have been widely used in high-end manufacturing, scientific research, national defense technology, and other fields, serving as essential equipment for precision measurement in many key national projects and international cooperation initiatives. For more industry solutions and typical cases, please contact API China.

Figure 4: API Headquarters Building

About API

The API brand was founded by Dr. Kam Lau in 1987 in Rockville, Maryland, USA. He is the inventor of the laser tracker and holds multiple patents for globally leading measurement technologies, making him a leader in the field of precision measurement technology. Since its establishment, API has been dedicated to the research and production of precision measurement instruments and high-performance sensors in the mechanical manufacturing sector. Its products are widely used in advanced manufacturing fields around the world and are at the forefront of high-precision standards in coordinate measurement and machine tool performance testing.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

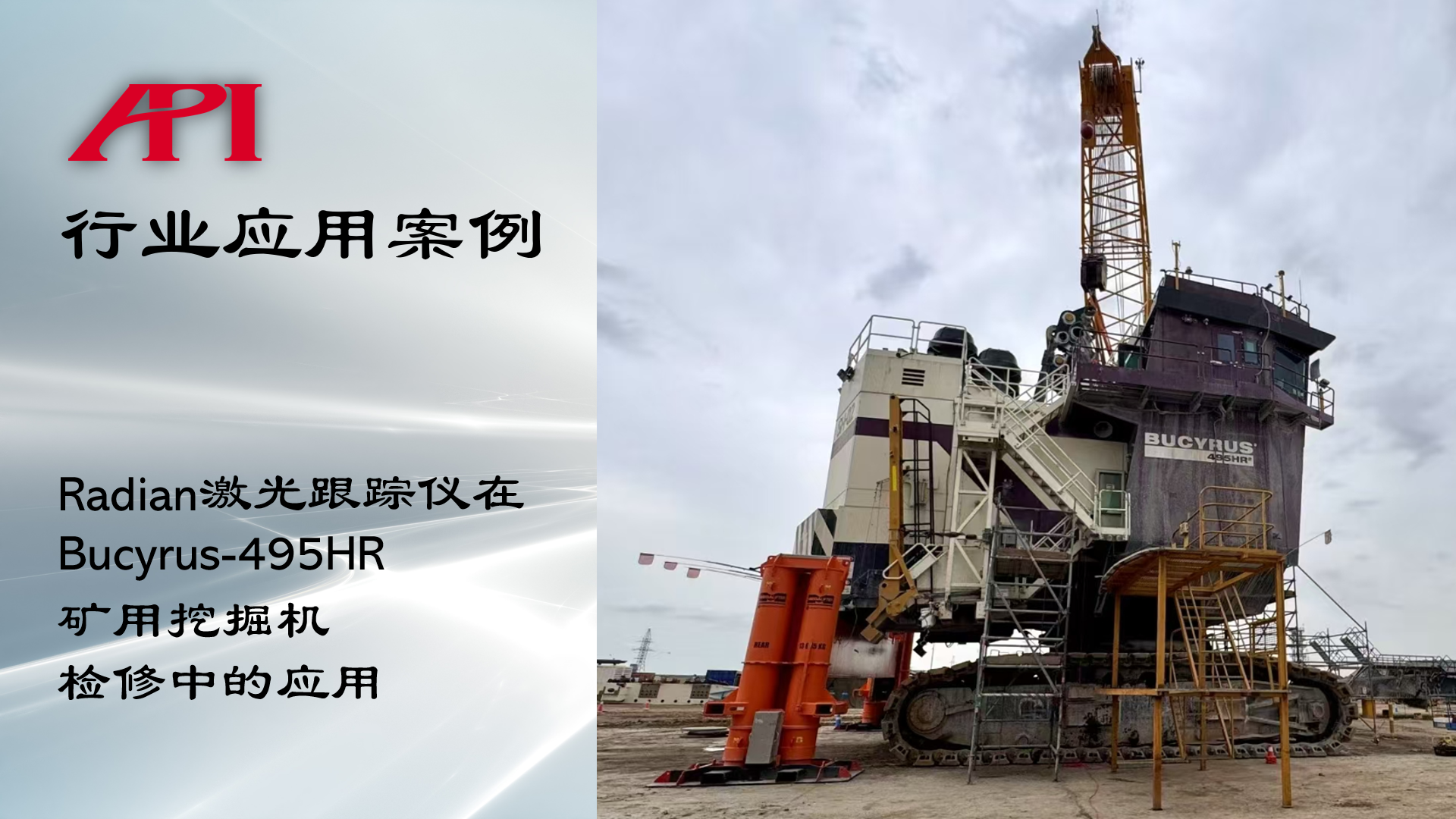

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

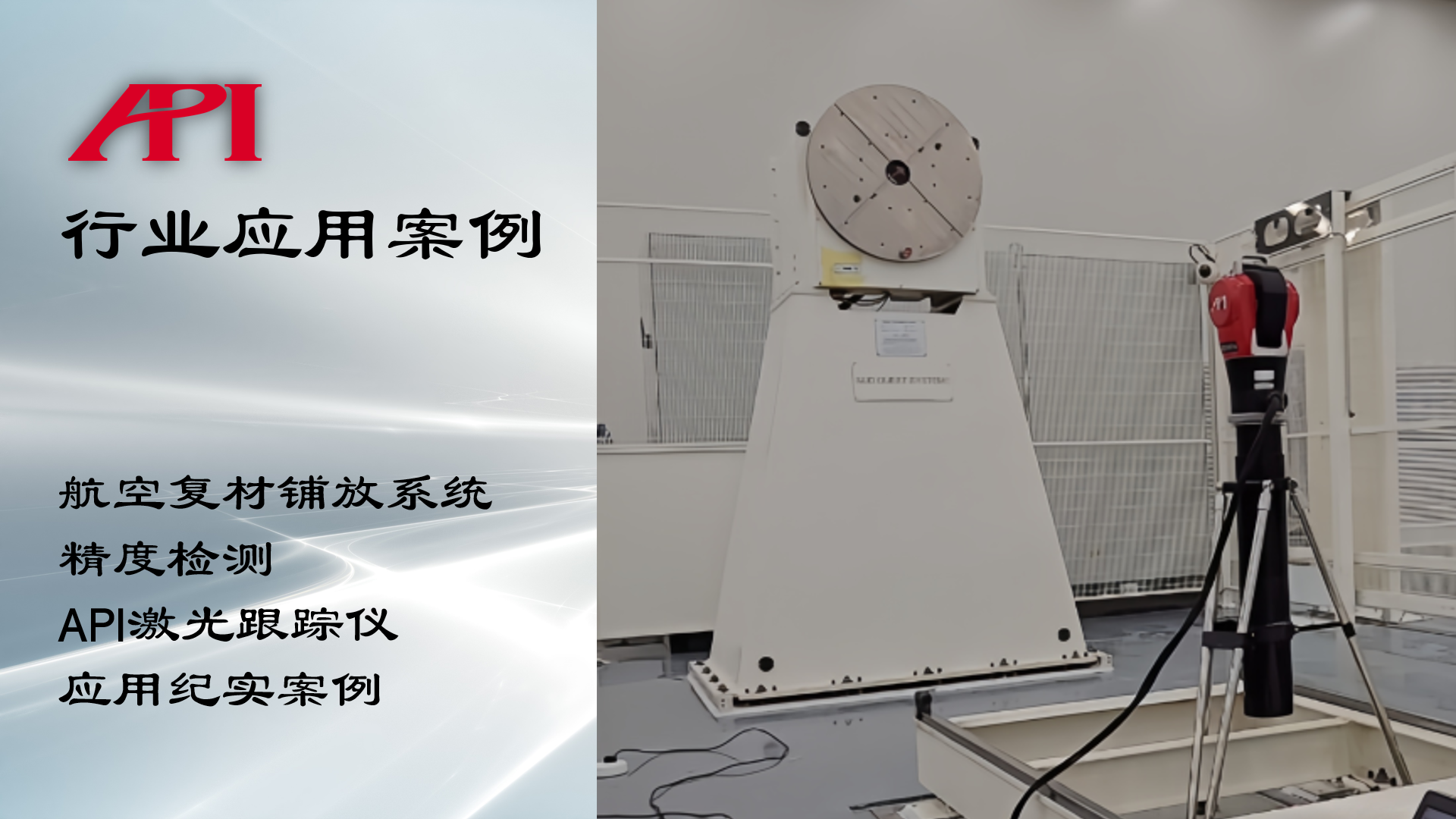

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858