Rapid Detection of CNC Machine Tools

Time cost is of great significance to manufacturing enterprises. Therefore, controlling time costs in various production processes is a key aspect of modern enterprises' efforts to reduce costs and increase efficiency. For core production equipment such as CNC machine tools, every second of operation or downtime directly affects the economic benefits of the enterprise. Thus, minimizing the time spent on downtime for inspection and maintenance becomes a critical factor in reducing time costs.

High-Efficiency Detection of CNC Machine Tool Accuracy and Rapid Performance Evaluation

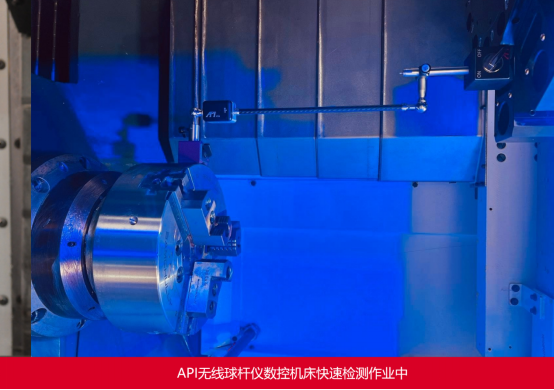

In response to the modern enterprise's demand for rapid evaluation and detection of CNC machine tools, the API brand has launched a wireless ballbar that can specifically achieve rapid detection and evaluation of machine tool performance in various application scenarios, including but not limited to: factory inspection and acceptance of new machines, daily checks of machine tool equipment, troubleshooting of machine tool faults, calibration after relocation or major repairs, and optimization of processing technology.

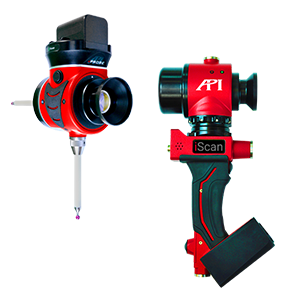

API Wireless Ballbar

The API wireless ballbar is a high-quality solution for rapid detection and evaluation of CNC machine tools. Its working principle involves installing the ballbar at both ends on the spindle and the worktable of the machine tool (or on the spindle and turret), measuring the circular trajectory formed by the movement of the two axes, and comparing this trajectory with the standard circular trajectory to evaluate the types and magnitudes of errors produced by the machine tool

Figure 1: API Wireless Ballbar

Measurable Items

The API wireless ballbar, equipped with various targeted measurement accessories, can achieve rapid measurement and comprehensive evaluation of key error parameters such as backlash error, straightness error, perpendicularity error, scale mismatch error, sliding error, servo error, and creeping error in machine tools.

Figure 2: API Wireless Ball Bar and Extended Rod Functional Expansion Accessories

Application and Features

The API wireless ball bar can be widely used in various CNC lathes, vertical/horizontal machining centers, etc. It can measure, identify, and diagnose errors in machine tools and servo systems within a 360-degree path range. Powered by batteries and utilizing Bluetooth data transmission, it achieves an 8-hour working endurance, truly enabling smooth wireless measurement and data transmission. Its compact body and design allow it to perform excellently in various measurement environments, even in confined spaces, while maintaining high performance.

Main Performance Parameters:

Resolution: 0.075μm

Accuracy: ±(0.5 + 0.1%L) μm

Range: ±1.5mm

Sampling Rate: 1000Hz

Figure 3: API Wireless Ball Bar Application Site

Simple and Convenient Operation

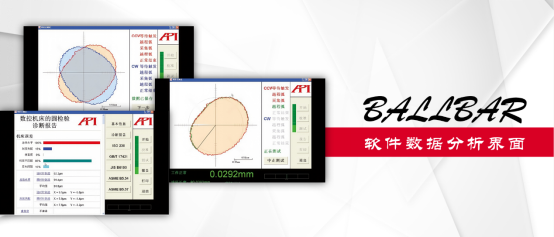

The VeriCal software, which integrates API with practical application development, features clear markings and indications, allowing users to intuitively collect and analyze testing data in conjunction with the measurer, quickly identify the root causes of issues, generate error graphs, and produce testing reports.

Figure 4: Data Analysis Interface of the Ball Bar Software

Figure 5: API Wireless Ball Bar Application on Site (with Extension Rod)

Comprehensive Diagnostic Solutions for Machine Tools

In addition to the wireless ball bar, the API brand's MTC (Machine Tool Calibration) series products also include:

XD Laser Interferometer (providing efficient calibration of 21 parameter errors for machine tools, with a 5-fold increase in efficiency), Swivelcheck Angular Measurement Instrument (solving all machine tool angular error issues including ABC angles), and Spindle Analyzer (real-time monitoring and analysis of spindle dynamic and thermal deformation errors).

Providing assurance for the high-precision performance of CNC machine tools from all aspects, safeguarding your production.

Figure 6: Overview of API Machine Tool Calibration Series Products and Features

About API

The API brand was founded by Dr. Kam Lau in 1987 in Rockville, Maryland, USA. He is the inventor of the laser tracker and holds multiple patents in globally leading measurement technologies, making him a leader in the field of precision measurement technology. Since its establishment, API has been dedicated to the research and production of precision measuring instruments and high-performance sensors in the mechanical manufacturing field. Its products are widely used in advanced manufacturing sectors around the world and are at the forefront of high-precision standards in coordinate measurement and machine tool performance testing.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

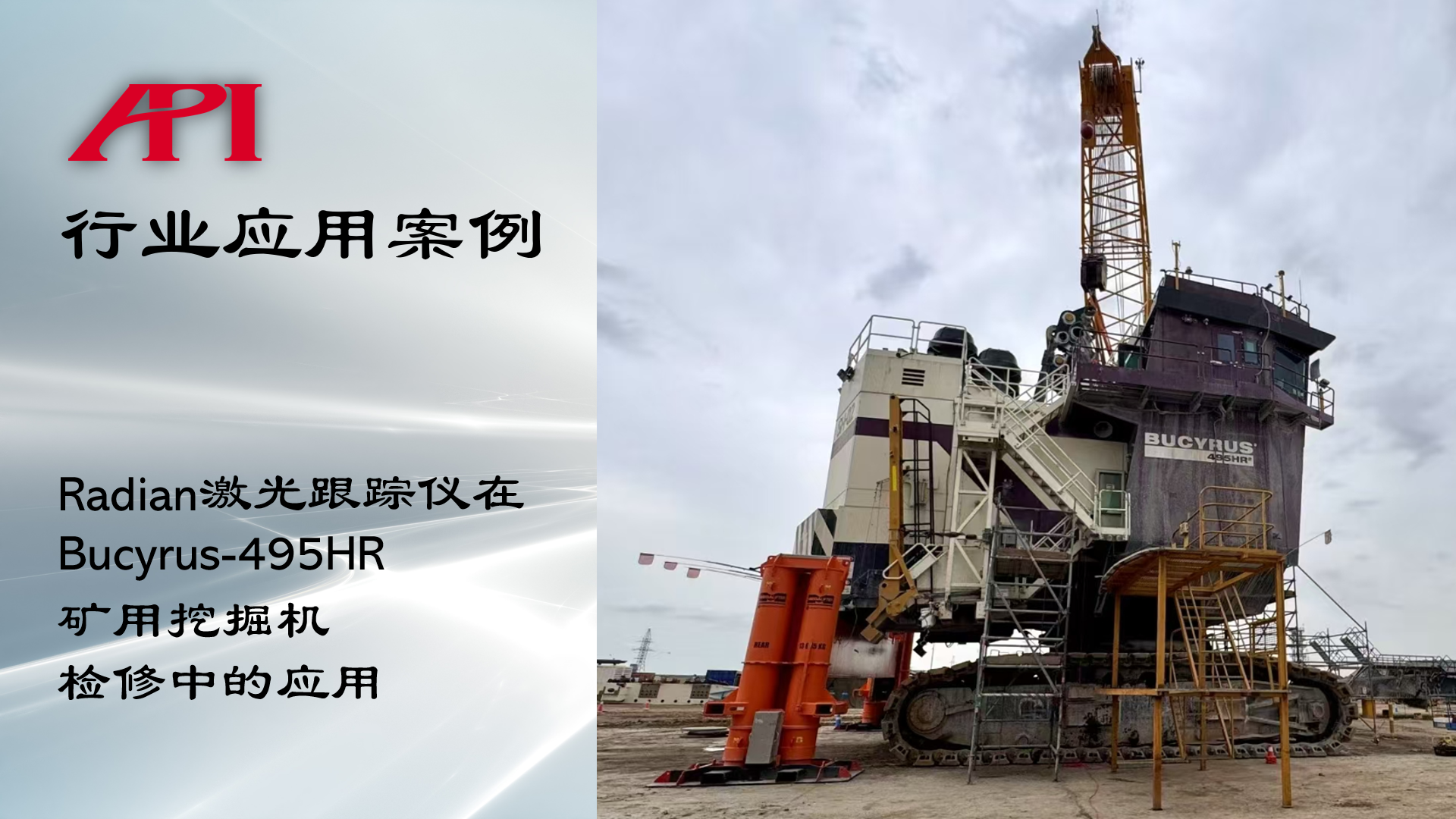

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858