About FDM 3D Printers

FDM (Fused Deposition Modeling) printing technology refers to the construction of three-dimensional objects by layer-by-layer stacking of thermoplastic materials. This technology is widely used in the consumer-grade 3D printer field. Since the technology requires melting the filament and then stacking it layer by layer to form the object, it inevitably produces layer textures on the printed parts. If the layer textures are not properly managed, they can affect the printing accuracy and level of detail.

Figure 1: Illustration of the Impact of Poor Layer Textures

Detection Requirements for FDM 3D Printers

Based on the structural characteristics and operational features of FDM 3D printers, key indicators such as linear accuracy, straightness accuracy, perpendicularity accuracy, and repeatability often need to be tested when detecting FDM 3D printers. This comprehensive evaluation assesses the actual performance of the tested 3D printer and calibrates any deviations to ensure the printer's performance, producing printed products that meet the requirements.

Figure 2: The 3D Printer and XD Laser Interferometer to be Tested in This Case

Problems Encountered by the Customer

The 3D printer model to be tested by the customer is very compact, leaving little space to set up detection equipment. Additionally, due to the narrow internal space of the 3D printer, a compact and convenient conical mirror design is required, while minimizing the need for additional fixtures to measure as much data as possible. Before inviting the API team for measurements, the customer had made multiple attempts to use various conventional laser interferometers for detection, but the results were unsatisfactory.

API Solutions and Advantage Analysis

After fully understanding the customer's testing requirements and challenges, API provided a solution for testing the 3D printer using the XD Laser 3D laser interferometer.

The XD Laser 3D laser interferometer can simultaneously measure linearity and straightness accuracy with a single installation. When implementing the aforementioned measurements, it has certain advantages over conventional laser interferometers. This article will explain these advantages in conjunction with the issues and measurement difficulties encountered by the customer during actual measurements:

Two-Point Alignment

The entire series of XD Laser laser interferometers adopts a compact, highly integrated optical path design, integrating the interferometer mirror with the main unit. There is no need to set up the interferometer mirror separately; only the laser head and target need to be aligned at two points. This avoids the complexities and large spatial requirements associated with the three-point alignment of conventional laser interferometers. Therefore, even for the compact 3D printer in this case, it can still be smoothly installed and efficiently complete the testing operations.

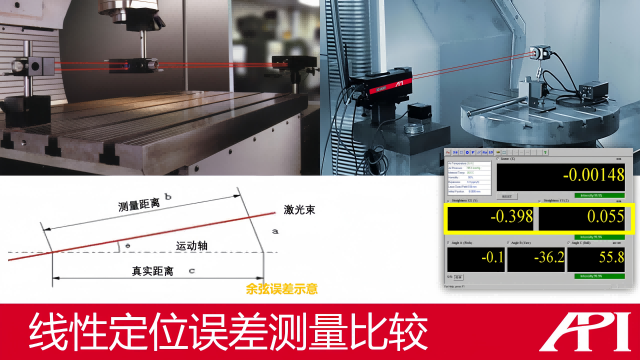

Figure 3: Comparison of Linear Measurement between XD Laser Interferometer (Right) and Conventional Laser Interferometer (Left)

2. Effectively Reducing Cosine Error

When performing linear accuracy measurements, conventional laser interferometers require three-point alignment, which makes them prone to cosine errors (as illustrated in the lower left of Figure 3). During the alignment process, conventional laser interferometers rely on manual three-point alignment, and adjustments can only depend on the light intensity bar in the operating software. This can easily lead to a relatively large angle between the adjusted light path and the actual motion axis direction, resulting in significant cosine errors, causing the measured values to be less than the true values.

In contrast, when using the XD Laser laser interferometer for linear measurements, its two-point alignment feature, combined with the real-time display of digital straightness parameters (as illustrated in the lower right of Figure 3), allows for a targeted reduction of the angle between the laser light path and the motion axis in a digital format, significantly minimizing the impact of cosine errors.

3. Fast and Efficient Straightness Measurement

When using a conventional laser interferometer for straightness measurement, in addition to the interferometer mirror group, a dedicated straightness measurement mirror group is also required. During adjustment, not only must the optical path be collimated, but the laser beams split and directed to the upper/lower (or left/right) verticality mirrors must also remain perpendicular to the mirror surfaces. Furthermore, even when measuring the straightness of the same axis in both the upper and lower, as well as the left and right directions, the mirror group must be changed again, using dedicated mirror groups for measuring the straightness in the upper and lower, and left and right directions, and the optical path must be readjusted. Measuring the straightness of three axes requires at least six changes of the mirror group and adjustments of the optical path. If measuring a long-stroke axis (over 4 meters), a long-distance straightness measurement mirror group must also be replaced, making the process relatively cumbersome.

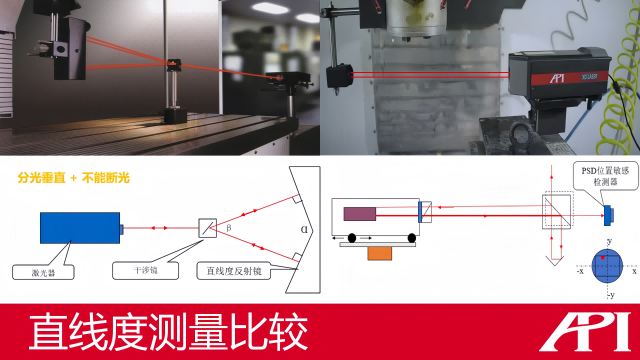

Figure 4: Comparison of linearity measurement between XD Laser interferometer (right) and conventional laser interferometer (left)

When measuring linearity errors using the XD Laser interferometer from the API brand, it only requires two-point optical installation. With the integrated high-performance PSD displacement sensor, it can easily detect both sets of linearity data (up and down, left and right) in one go. As shown in Figure 4, when the laser emitted from the XD Laser main unit hits the target, it splits into two beams. One beam reflects back to the main unit via a reflection device for linear data measurement, while the other beam goes to the high-performance PSD sensor for measuring linearity parameters. As illustrated in the lower right quadrant of Figure 4, when the laser hits the corresponding coordinate quadrant of the PSD sensor, the measurement of the linearity parameters is complete. The PSD sensor can then convert the optical signal into an electrical signal, which is fed back to the operator through a digital real-time display, making it simple and user-friendly.

In addition, conventional laser interferometers measure linearity data using an interferometer mirror group adjustment method, which does not allow for light interruption during the entire measurement process. Therefore, they are typically only used for the final evaluation of linearity data and are difficult to apply during the real-time adjustment phase of rail installation. The XD Laser interferometer, on the other hand, uses a high-performance PSD sensor to measure linearity parameters, ensuring excellent dynamic performance while maintaining measurement accuracy. It is not affected by light interruption and can measure, read, and display linearity parameters in real-time, making it applicable during the rail installation adjustment phase.

4. Convenient and easy operation for verticality measurement

Similar to linearity measurement, conventional laser interferometers require complex mirror group arrangements and optical path adjustments when measuring verticality error parameters. Since verticality measurement is based on the linearity parameters of two axes, using a conventional laser interferometer for verticality measurement necessitates the addition of a verticality measurement component on top of measuring the linearity of the two-axis mirror group. This requires splitting more optical paths to achieve data measurement and reading. Adjusting more than 10 laser optical paths is no easy task; it requires the operator to have considerable adjustment experience and skill to position the optical path optimally for measurement. Measuring the verticality of three axes pairwise would require three such installations and adjustments of the mirror group and optical path, resulting in relatively low efficiency.

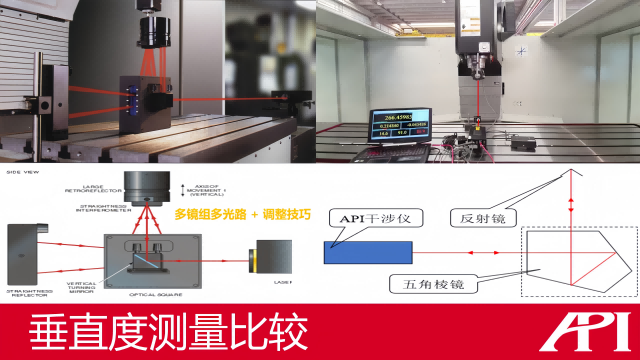

Figure 5: Comparison of verticality measurement between XD Laser interferometer (right) and conventional laser interferometer (left)

When using the XD Laser interferometer for verticality measurement, thanks to its high-performance PSD sensor, which measures linearity at a 1:1 ratio, only a pentagonal prism needs to be added at the corresponding position to ensure a 90-degree turn of the laser. This avoids the complex mirror group switching and optical path adjustment processes required when using conventional laser interferometers, significantly improving measurement efficiency.

Considering the actual measurement scenario of the client in this case, in addition to the above comparisons, using various complex mirror group combinations also requires a large working space. However, such a compact 3D printer cannot provide the space needed for complex mirror group installations, which is why the client was unable to successfully achieve verticality measurement of the 3D printer using various brands and models of traditional laser interferometers.

Figure 6: XD Laser interferometer

More expansions

In this case, the API provides customers with the XD Laser 3D laser interferometer, which can simultaneously measure three parameters (i.e., X, Y, Z) in one installation, easily achieving the measurement and detection of straightness errors.

In addition to the 3D model, based on the diverse measurement application needs of customers, the API brand also offers XD Laser laser interferometers in 1D, 5D, and 6D models. The 6D model can measure six parameters (X, Y, Z, yaw angle, pitch angle, roll angle) simultaneously in one installation, with options for standard (measurement accuracy of 0.5μm/m) and precision (measurement accuracy of 0.2μm/m) types, fully meeting the measurement needs of daily production and laboratories.

Figure 7: Measurement site of this case

On-site application

As shown in Figure 7, this is the operation site where the API brand XD Laser 3D laser interferometer measures a small FDM 3D printer. The compact receiving mirror, combined with the two-point alignment installation method, fully adapts to the customer's measurement environment and meets their measurement needs.

相关新闻:

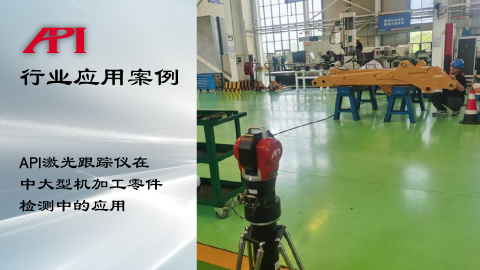

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

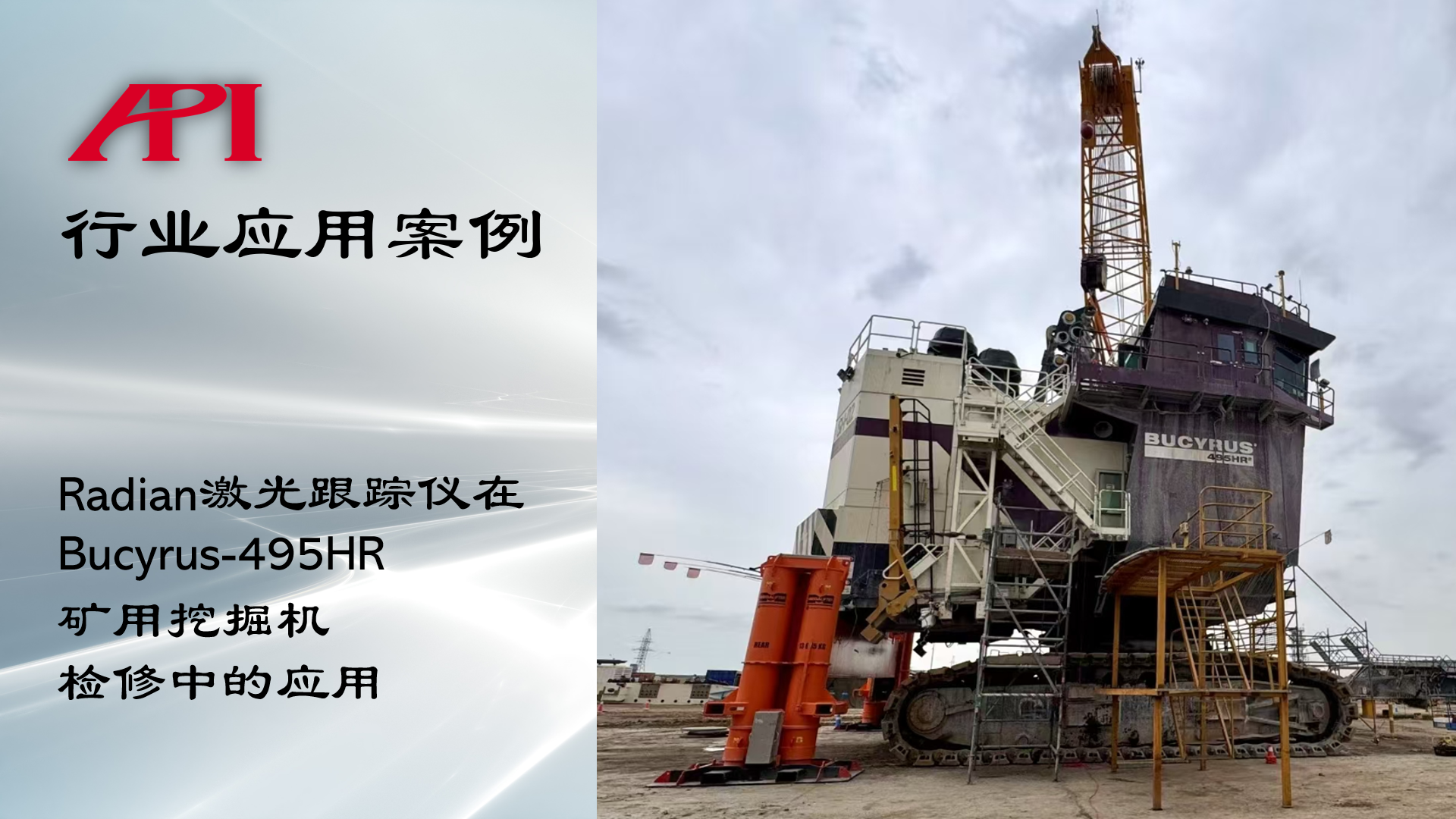

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

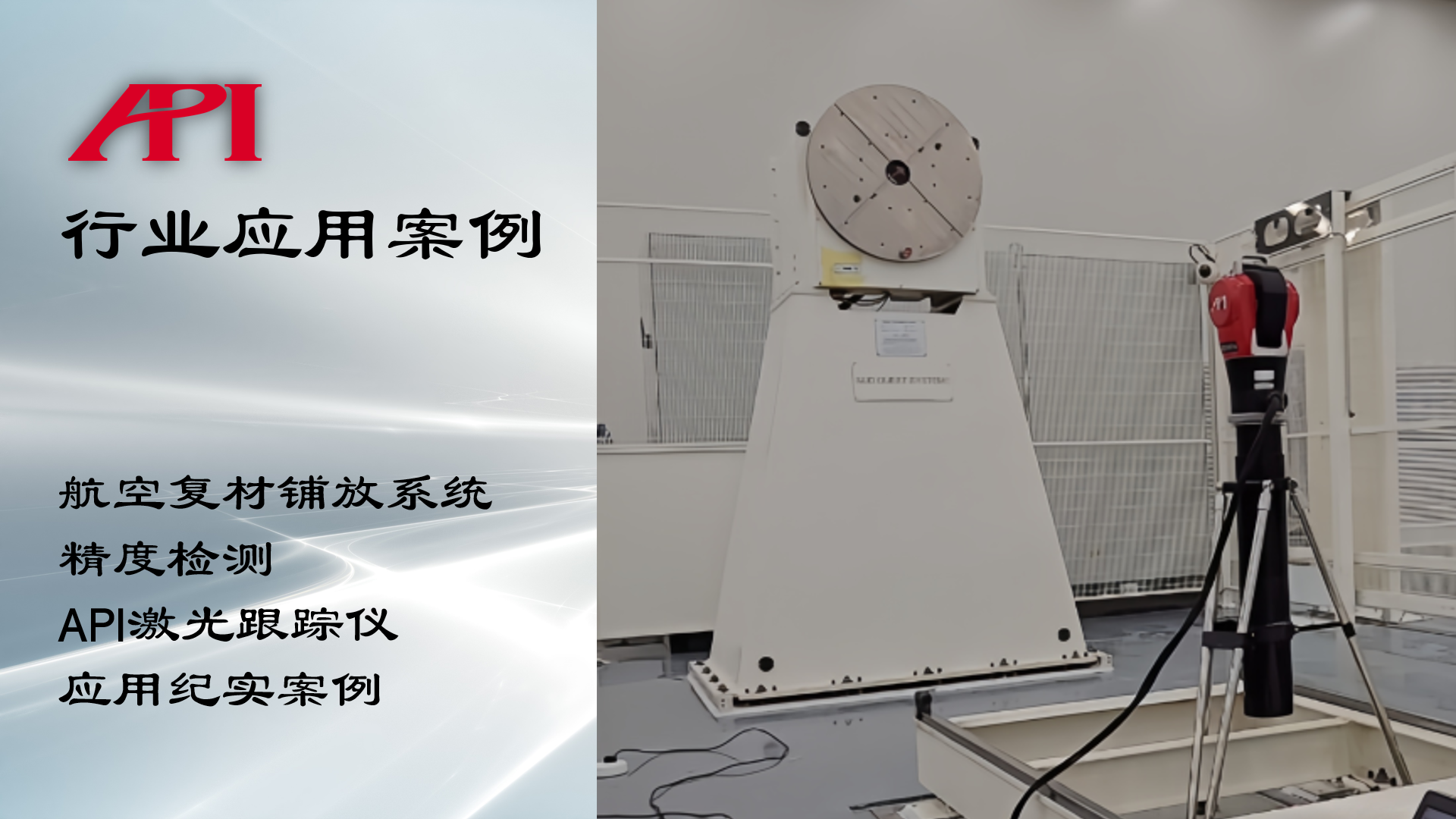

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858