Importance of Large Marine Generators and Inspection

Marine generators play a crucial role in providing power for ships. Large marine generators not only supply electricity for lighting, communication equipment, and navigation systems but also provide power for driving equipment such as ballast pumps, oil pumps, and water pumps, while ensuring energy supply to support the operation of important facilities like onboard lifting equipment, winches, and boilers. It is evident that large marine generators are an indispensable component of large vessels and play a key role during navigation.

Therefore, large marine generators need to maintain an extremely stable operating state, which requires meticulous attention to detail in their manufacturing, assembly, and regular inspection and maintenance to provide sufficient assurance and support for their proper operation.

Customer Requirements & Inspection Challenges

Customer Requirements: Measure the diameter, cylindricity, and coaxiality of the multi-segment wedge of the permanent magnet rotor and stator of a specific model of large marine generator to ensure the uniformity of the fit between the stator and rotor.

Inspection Challenges and Issues to be Resolved:

① The permanent magnet rotor has a strong magnetic force, and the surface is coated with paint and small particles, making it quite troublesome to measure with conventional inspection equipment and tools. It is easily attracted by the permanent magnet rotor, causing difficulties in measurement or rendering it impossible, which poses significant challenges for measurement;

② During assembly, the protruding position of the wedge on the stator has varying dimensions of roundness and cylindricity, which can easily cause the stator and rotor to jam during fitting. It is urgent to know the deviations through measurement and inspection methods to resolve this issue.

Traditional Measurement and Inspection Methods

In traditional inspection methods, multiple instruments such as a roundness measuring frame, total station, level, internal/external micrometers, and piano wire electrical measurement methods must be used in combination to obtain the final data results. The complexity of the overall equipment combination measurement method increases exponentially. Although these measurement methods can ultimately yield inspection data, it is generally difficult to ensure comprehensive installation and assembly accuracy, which can easily lead to systematic errors and rework.

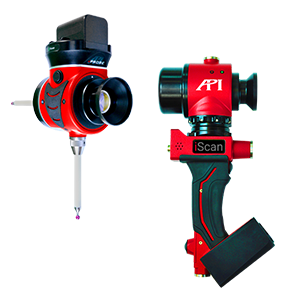

Figure 1: Radian Series Laser Trackers (from left to right: Plus model, Pro model, Core model)

Radian Laser Tracker Inspection Scheme

Laser tracker measurement technology has been widely applied in precision industrial measurement fields such as aerospace, aviation, shipbuilding, and machining. Its characteristics of long measurement distance and high precision make it very suitable for the measurement and inspection applications of large marine generators, especially in aspects such as generator installation and fit inspection, where its advantages in precision and efficiency are particularly evident.

In this case, the Radian Plus model laser tracker is used for inspection, which features high precision (micron level) and large-scale measurement (diameter exceeding 160 meters), while completely avoiding the troubles of various wires. It utilizes battery power and wireless data transmission, truly achieving wireless operation with an effective working endurance of over eight hours.

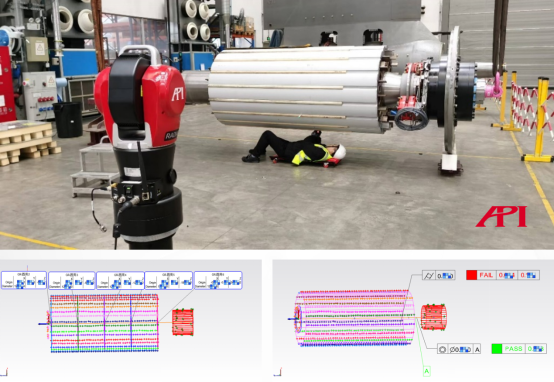

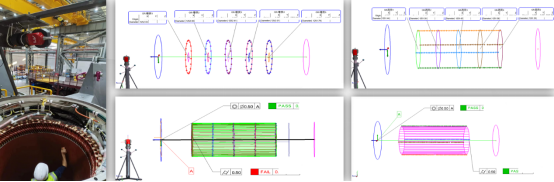

Figure 2: Rotor Measurement Site and Data Analysis of This Case

Figure 3: Stator Measurement Site and Data Analysis of This Case

Measurement Site Operation Implementation Process

During measurement, the Radian laser tracker is first set up at a suitable position with a clear line of sight to the measurement point. The operator holds the laser tracker target sphere (S MR) with a built-in prism and touches the position to be measured. The Radian laser tracker emits a laser and locks onto the center position of the target sphere in real-time. When the operator stabilizes the target sphere at the measurement position or issues a data collection command, Radian will measure the 3D coordinates of the target point at a data collection rate of 1,000 Hz and send the measurement data in real-time to the computer software for storage, for subsequent analysis. Once data collection for all points is completed, corresponding lines, surfaces, and volumes can be constructed, and data models can be imported for shape and position tolerance analysis or data model comparison, achieving the purpose of measurement and inspection.

For the measurement site and data analysis interface of the motor stator and rotor in this case, please refer to Figures 2 and 3.

Summary

The API brand Radia n laser tracker, with its outstanding accuracy, flexibility, and measurement range, fully meets the detection needs of large marine engines in this case. Its simple operation and user-friendly interface enhance efficiency, providing strong assurance for the high quality and efficiency of the entire measurement operation.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858