About Contract Measurement Services

In the fields of industry and manufacturing, contract measurement services typically refer to the provision of measuring instruments and professional application engineers by service providers, who come to the client's site to develop measurement plans according to the client's established requirements, perform measurements on the targets, and issue professional measurement reports. Additionally, contract measurement services may include equipment rental, equipment maintenance, personnel training, data analysis, and more.

Since industrial-grade/laboratory-grade precision measurement equipment is usually quite expensive, manufacturing enterprises can customize measurement plans on demand by using contract measurement services, thereby avoiding costs related to equipment procurement, personnel training, and professional skill development, thus adding value and efficiency to production.

API is a trusted provider of precision measurement services

In the field of contract measurement services, API, as a manufacturer of precision 3D measurement instruments represented by laser trackers, possesses numerous advantages in providing contract measurement services:

· API has established offices in major countries and regions around the world and has assembled a high-quality team of engineers. Adhering to a customer-centric service philosophy, we provide you with excellent precision measurement services with a professional attitude and strict requirements;

· API is the inventor of the laser tracker and holds multiple patents for globally leading measurement technologies, making it a leader in the field of precision measurement technology;

· Since its establishment, API has been committed to the research and production of precision measurement instruments and high-performance sensors in the mechanical manufacturing field. Its products are widely used in advanced manufacturing sectors around the world and are at the forefront of high-precision standards in coordinate measurement and machine tool performance testing;

· API has a team of experienced and highly capable engineers who continuously develop advanced innovative products to meet the needs of rapidly evolving industrial technologies. API has been an active participant and key technical partner in numerous projects for the U.S. federal government, enterprises, and scientific research, and its achievements to date have earned it a high reputation in the international precision measurement field.

At the same time, API is a member of ASME B5.54, participated in the preparation of B89.4.19, provided calibration methods for the B89.4.19 calibration system, is a member of the B89.4.19 measurement system, and all brand measurement products have been certified by the National Institute of Standards and Technology (NIST) in the United States. They are widely used in internationally renowned metrology institutions such as PTB, NIM, and MNIJ. API measurement products comply with ISO17025 certification standards (certificate number: 2229.02), and API has been invited to provide measurement product/service solutions in many well-known international collaborations and national key projects.

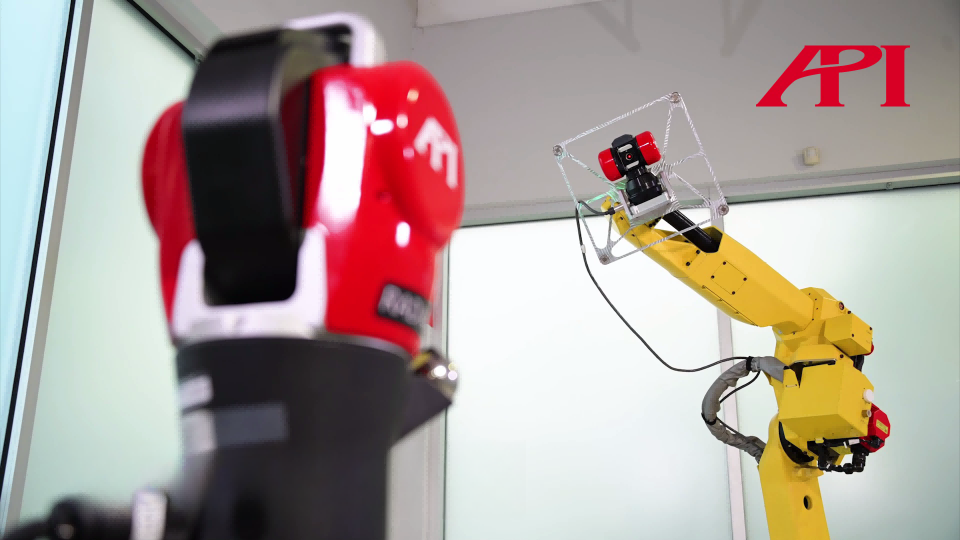

Figure 1: Laser Tracker Measurement Application Site

Main Measurement Services Provided by API

Laser Tracker Measurement Services

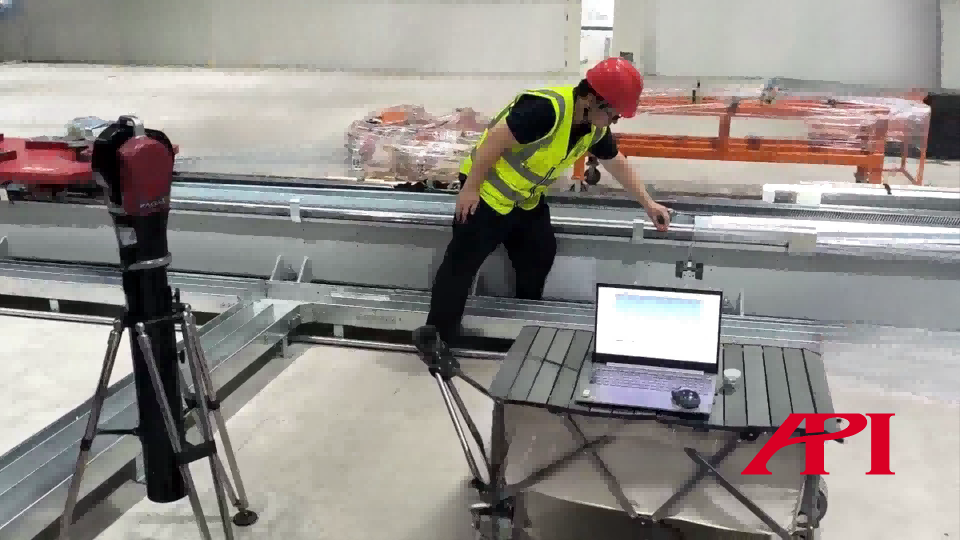

API can provide you with high-precision 3D and 6D static and dynamic measurement services based on laser trackers. API is the inventor and manufacturer of laser trackers, continuously improving their performance and expanding their application areas for nearly half a century, leading the development of the precision measurement industry for laser trackers.

API's laser tracker measurement services can provide solutions in areas including dimensional inspection, error analysis, data processing, gauge certification, tooling adjustment, production line installation guidance, industrial robot calibration, and spatial error compensation for large machine tools. API laser trackers feature ultra-high measurement accuracy, a large measurement range, reliable operational stability, and a compact, portable design, making them suitable for use in factories, outdoor environments, and laboratories. They can be used in conjunction with internationally recognized measurement software such as SpatialAnalyzer, Polyworks, BuiltIT, and Verisurf for measurement operations.

Applicable fields include:

· Especially suitable for all fields involving large-scale precision geometric measurement;

· Aerospace field for aircraft tooling inspection, dimensional and shape inspection of components, fuselage docking guidance, precision spraying guidance for fuselage, production line positioning installation guidance, and real-time monitoring of drone trajectories;

· Automotive manufacturing field for dimensional and shape inspection of components, white body inspection, tooling fixture inspection, gauge calibration, and installation guidance for growth lines;

· Component size and shape inspection in shipbuilding, detection of guide rail parallelism, propeller inspection, component docking guidance, and hull maintenance inspection;

· Detection of body dimensions, white body inspection, train bogie inspection, and track parallelism and flatness in the field of railway locomotive manufacturing;

· Detection of component dimensions and shapes, guide rail inspection, hinge point coaxiality inspection, and dynamic tracking measurement of motion trajectories in the field of heavy machinery manufacturing;

· Inspection of generator stators and rotors, turbine blade inspection, wind turbine hub hole position indexing inspection, wind turbine blade inspection, nuclear power pipeline inspection, and installation positioning guidance in the energy sector;

· Inspection of steel mill rolling mills, assessment, diagnosis, and testing before roller adjustment and repair;

· Inspection and calibration of rollers in lithium battery production winding machines, and installation positioning guidance for production lines;

· Calibration of industrial robots and spatial error compensation for large machine tools;

· Calibration of steering facilities in various fields of general manufacturing, dynamic measurement and calibration of AGV carts, 6 degrees of freedom (6DoF) measurement and real-time monitoring of test objects, and detection of positioning/straightness/flatness/verticality/parallels/angles/velocity/acceleration, etc.;

· Precision dynamic tracking monitoring in scientific research, large-scale precision measurement, inspection during the production process of optical components for precision instruments, and accuracy improvement of robotic machine tools;

· And more...

Figure 2: Application scenarios of 9D laser radar measurement

Laser Radar Non-Contact Precision Measurement Service

API's 9D laser radar is an excellent solution for non-contact large-scale precision measurement based on optical frequency domain interference technology. For measuring large targets that are inconvenient for personnel to touch, using the API 9D laser radar for non-contact scanning measurement can perfectly meet user needs.

This measurement service is particularly suitable for measuring automotive frames and for measuring or assembling large components (such as aircraft parts).

Figure 3: On-site robot calibration measurement service

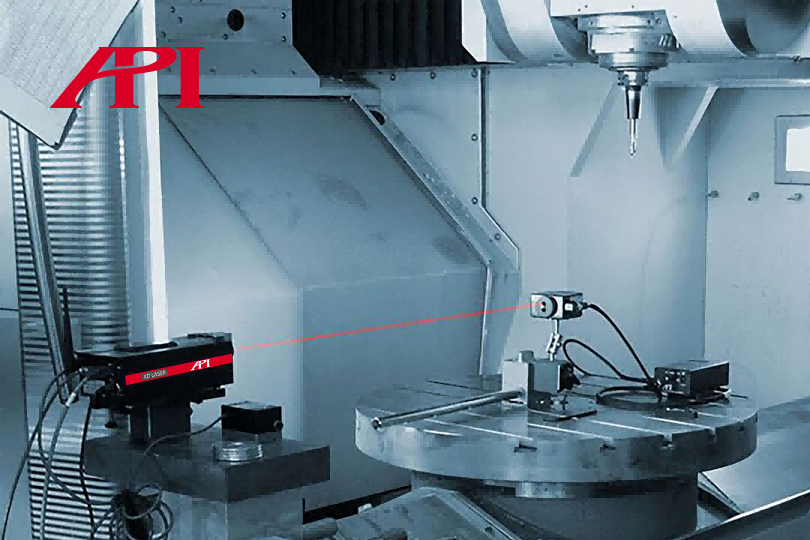

Figure 4: On-site machine tool calibration measurement service

Machine Tool/Robot Calibration Measurement Service

API can provide calibration and inspection services for various machine tools. Nearly half a century of research on machine tool errors and technological accumulation has resulted in API's expert-level machine tool inspection service solutions. Professional measurement service engineers and high-precision instruments are here to solve various error problems in machine tool production or use:

· Perfectly solve 21 parameter error issues of machine tools;

· Address all machine tool angular error issues, including ABC angles;

· Real-time monitoring of dynamic and thermal deformation errors of machine tool spindles;

· Quick detection of CNC static/dynamic comprehensive accuracy;

· Improvement of precision in large multi-axis machine tools (spatial error compensation);

· Calibration of industrial robots;

· And more...

The instruments and equipment used for API machine tool testing are specifically developed and manufactured based on API's rich technical accumulation in the machine tool testing industry; they feature precision and efficiency. They quickly diagnose machine tool error parameters, effectively reduce downtime, and ensure the safety of your production:

· Detection of positioning accuracy and repeatability;

· Detection of backlash;

· Detection of X, Y, and Z axes;

· Detection of verticality;

· Detection of guide rail parallelism;

· Detection of flatness;

· Detection of diagonals;

· Detection of machine tool speed and acceleration;

· Detection of rotary table angle errors;

· Detection of spindle dynamic and thermal deformation errors;

Figure 5: Remote training site

Measurement software/hardware personnel training

As a leading manufacturer and supplier of precision measurement equipment in the industry, API excels in training customers on how to maximize the performance of their equipment and provides training on related software functionalities. Training can be conducted at the API training centers (China: Beijing, Shanghai, Suzhou, Chengdu) or at the customer's site. Customers will need to pass a training test and will subsequently receive a training completion certificate issued by API.

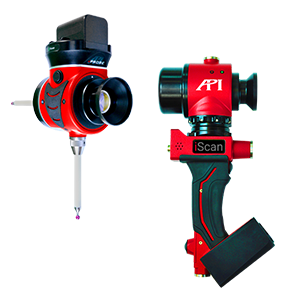

API offers comprehensive software/hardware training for a full range of measurement and inspection products, including: Radian laser tracker, XD Laser interferometer, Spindle analyzer, Swivelcheck angle check instrument, Arm series articulated arms, ball bar, Rapidscan laser scanner, Spatial Analyzer, Polyworks, Verisurf, Metrologic, and more. Training is conducted by experienced application engineers who provide on-site instruction and share measurement experiences, while also addressing practical questions.

Equipment rental

We provide precision measurement equipment rental services that are well-maintained, suitable for various working conditions, meet a wide range of measurement needs, and are reasonably priced, ensuring comprehensive support for your successful measurements.

· Radian Pro laser tracker

Radian Plus Laser Tracker

· Radian Core Laser Tracker

· ActiveTarget Active Target

· STS Six-Dimensional Intelligent Sensor

· vProbe Hidden Point Intelligent Probe

· iScan3D Intelligent Scanning Probe

· Rapidscan Fast Optical Scanner

· Arm Joint Arm

· XD Laser Interferometer

· Swivelcheck Angle Swing Checker

· SpindleAnalyzer Spindle Analyzer

· Ball rod instrument

On-site demonstration of partial API contract measurement services:

Figure 6: On-site detection of robot guide rail parallelism/flatness

Figure 7: On-site robot calibration operation

Figure 8: On-site detection of turbine rotor band & shaft diameter

Figure 9: On-site measurement service for turbine maintenance

Figure 10: On-site measurement of construction machinery components

Figure 11: On-site measurement service for roller verticality adjustment

Figure 12: On-site calibration measurement service for boring and milling machining center

API precision measurement service – Treating every measurement with focus and rigor, and returning every trust with precision and efficiency!

Figure 13: API Company Headquarters Building

About API

The American Precision Industries, Inc. (API) was established in 1987 and is headquartered in Rockville, Maryland, USA. Since its inception, API has been dedicated to the research and production of precision measuring instruments and high-performance sensors in the field of mechanical manufacturing. Its products are widely used in advanced manufacturing sectors in the United States and around the world, and the company is a leader in high-precision standards for coordinate measurement and machine tool performance testing. API boasts a team of experienced and highly capable engineers who continuously develop advanced innovative products to meet the rapidly evolving demands of industrial technology. API is an active participant and key technical partner in numerous projects for the U.S. federal government, businesses, and scientific research. The achievements it has made to date have earned it a high reputation in the international precision measurement field.

相关新闻:

API laser tracker is Application in the Inspection of Medium and Large Machined Parts

Project BackgroundClient Company: A large manufacturing enterprise;Industry: Hig

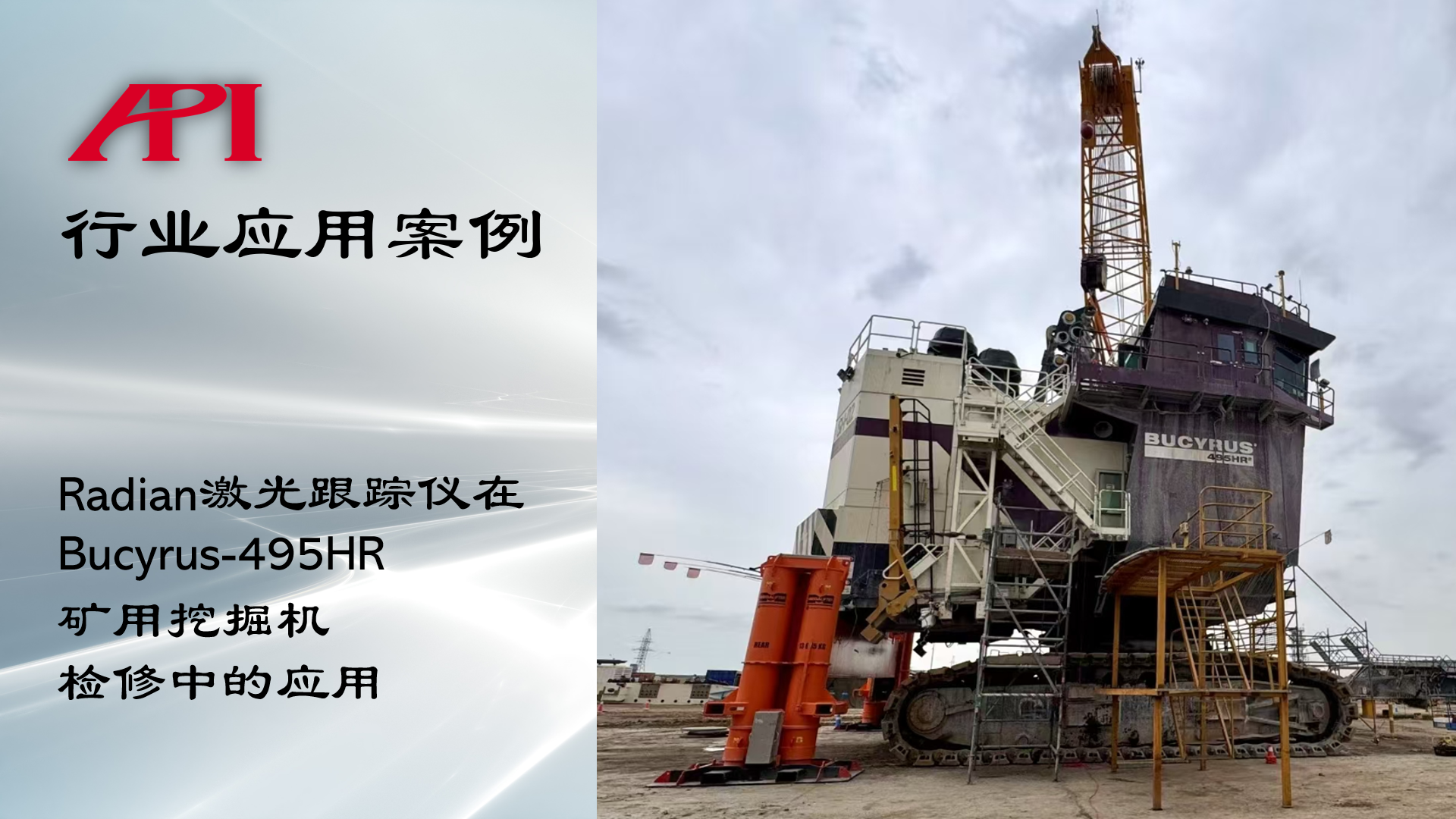

Radian laser tracker at Bucyrus 495HR Application of Mining Excavator Maintenance

Overview of Bucyrus 495HR Mining Excavator and Maintenance The Bucyrus 495HR min

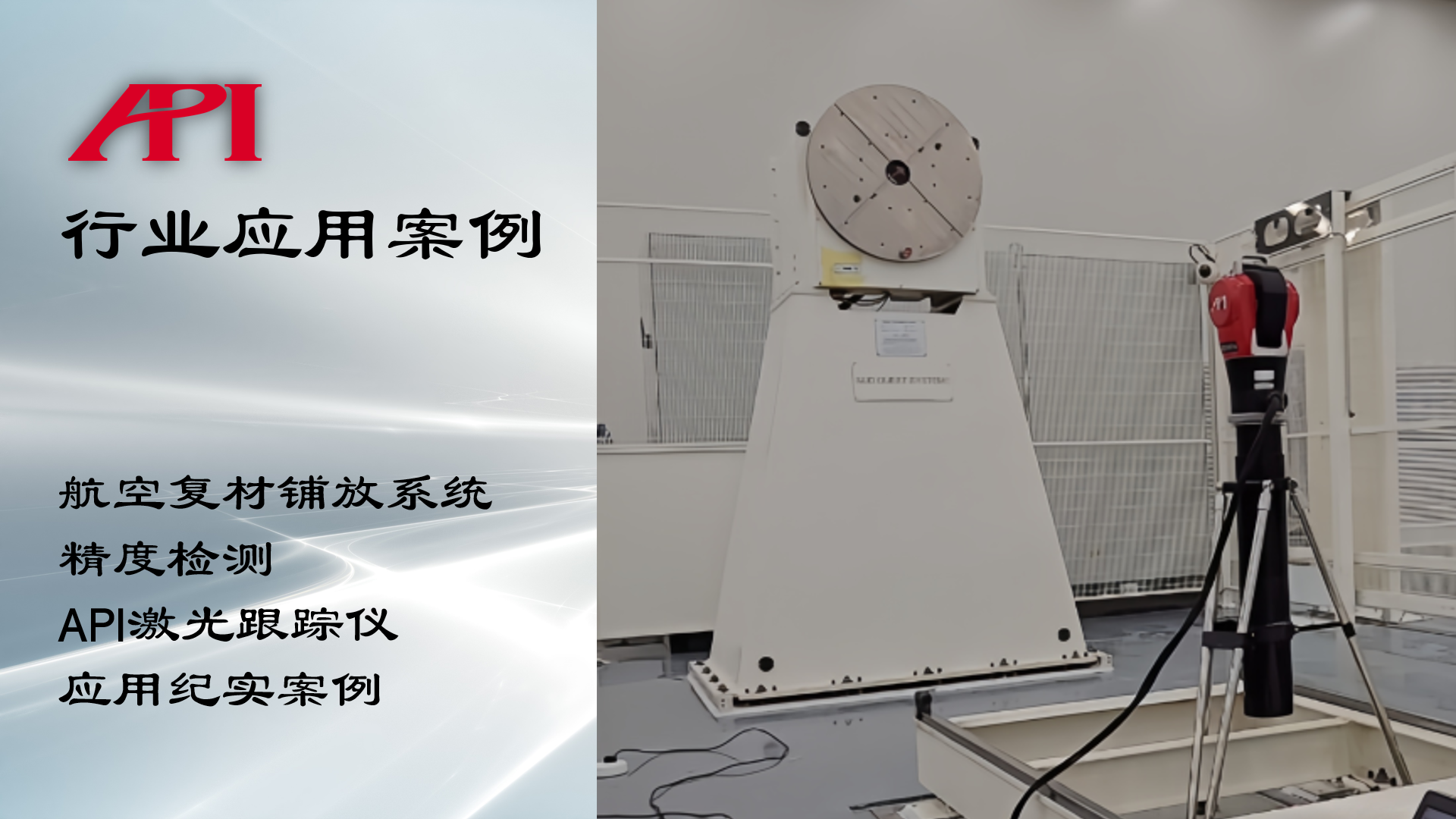

Aerospace Composite Material Laying System Precision Detection Radian Laser Tracker Application Cas

About Aerospace Composite MaterialsAerospace composite materials are primarily u

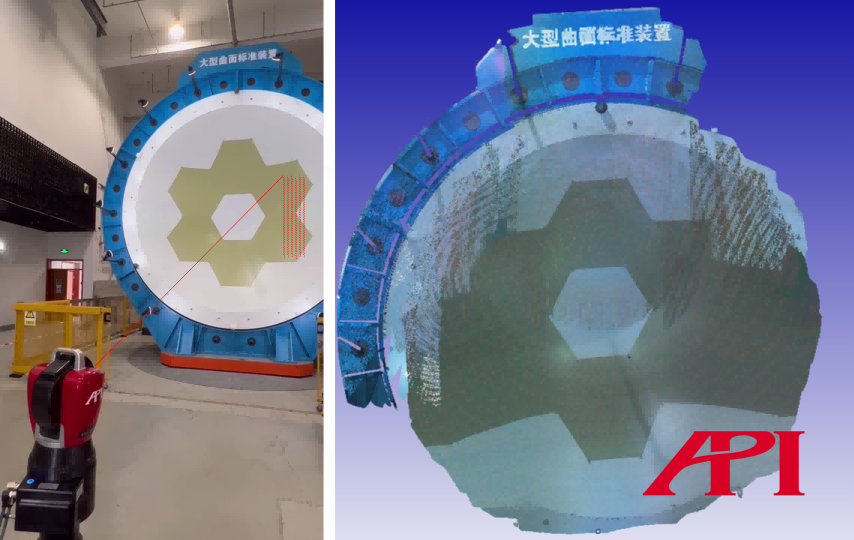

3D Measurement Solutions for Large Oil Equipment

3D Measurement and Inspection of Large Oil EquipmentIn the oil equipment manufac

Learn More:

激光跟踪仪靶球&测头

Maximize laser tracker productivity with hand held and 激光跟踪仪主动靶标.

Learn More /laser-tracker-targets

XD Laser CMM Calibration

The XD Laser is the only assessment system that can measure all 6 error parameters simultaneously in a single set-up

Learn More /xd-laser

API Reverse Engineering Service

Reverse engineering services include scan as-built parts to creation of a 3D digital point cloud and CAD Model.

Learn More /reverse-engineering/

+86 10 59796858

+86 10 59796858